- Joined

- Jan 11, 2018

- Messages

- 308

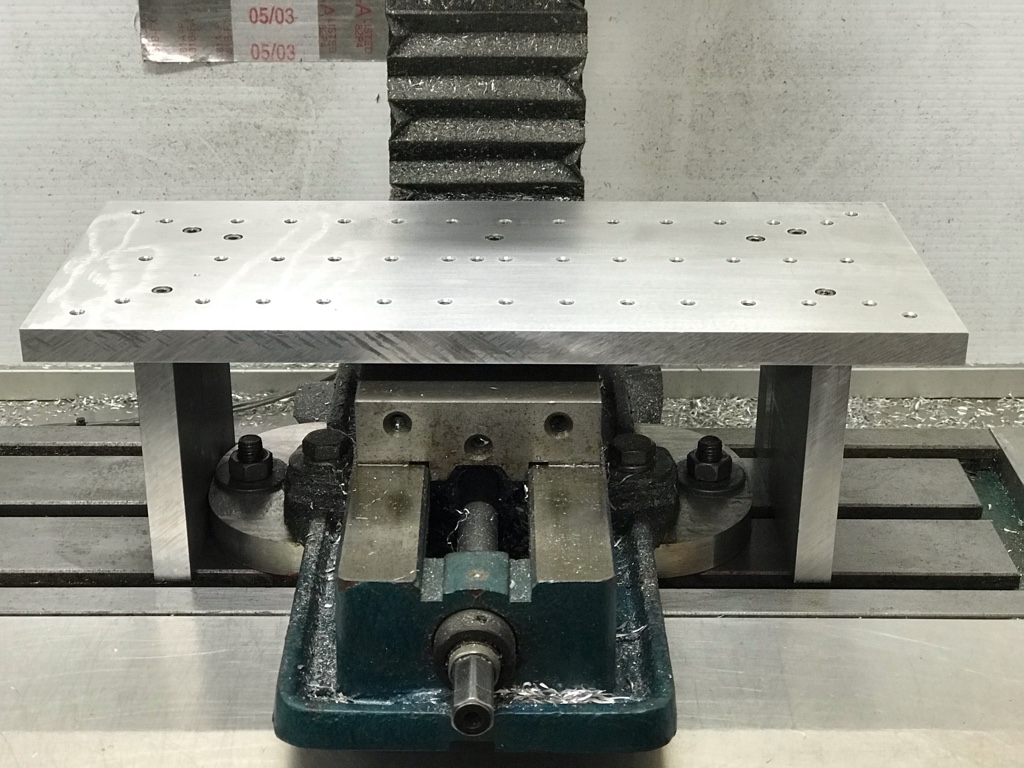

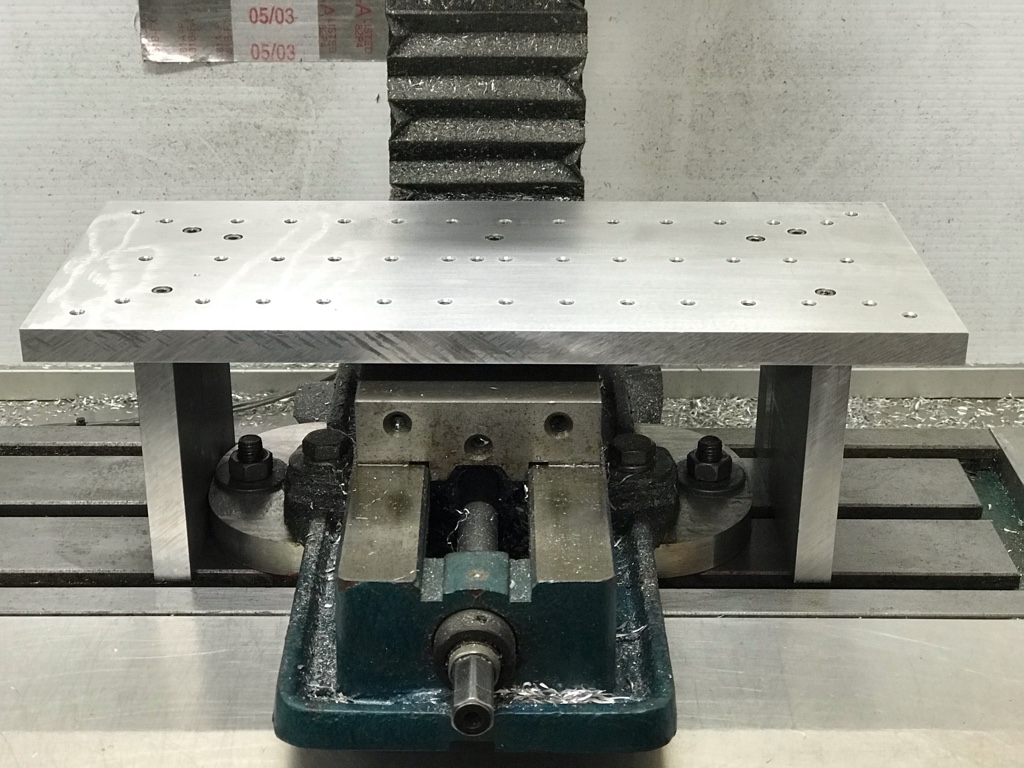

I have a CNC converted Grizzly G0704. It only has 6.5” x 18” of travel so it’s hard to have any usable space left over on the table once the vise is mounted. I have a few products that I route from G10 fiberglass or aircraft plywood. I used to bolt a sheet of MDF to my mill’s table to use as a spoil board but I quickly tired of having to remove the vise and then putting it back on and realigning it every time.

I came up with this riser table design a few years ago. It has a cross member that clamps in the vise and is repeatable. I made the first one from 3/4” MDF but it was destroyed in an accident earlier this year. I decided to make V2 from 5/8” aluminum plate. I drilled and tapped a series of holes so I can clamp materials directly to the table. I also made a few spoil boards from 1/2” MDF so I can route parts out of a sheet without damaging the table.

I came up with this riser table design a few years ago. It has a cross member that clamps in the vise and is repeatable. I made the first one from 3/4” MDF but it was destroyed in an accident earlier this year. I decided to make V2 from 5/8” aluminum plate. I drilled and tapped a series of holes so I can clamp materials directly to the table. I also made a few spoil boards from 1/2” MDF so I can route parts out of a sheet without damaging the table.

.

.