- Joined

- Feb 15, 2018

- Messages

- 16

thanks J - I'll mention the planer at bottom...

update on the mill:

bad start cap for one thing...

...but was it ever good being run on 110v even when it “worked”?

So:

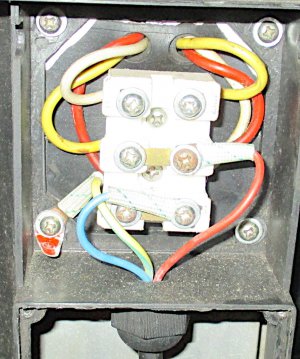

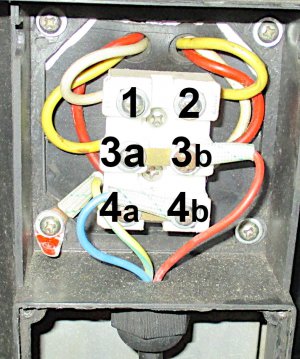

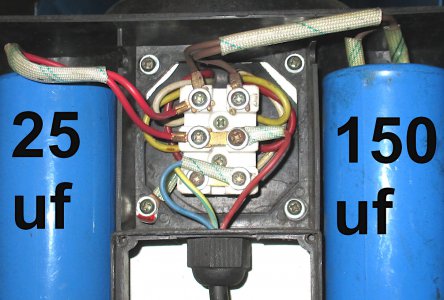

The motor capacitors are:

CD60, 220/265 V.A.C., 150 MFD

(presumably the START cap)

*THIS one tests BAD (meter says 0.F)

- - - -

CBB60 SH, 450 V.A.C., 25 MFD

(presumably the RUN cap)

This tests 23.88 MFD on the outside of within +/- 5% tolerance

* So it's staring to look like the theory of it not having enough oompf and getting to speed?

Question: If it's not getting to speed (and it does seem sluggish starting) then I presume the <click> is not the centrifugal switch successfully tripping but rather, what (?) a thermal breaker (like it sounds) tripping because startup is straining and/or taking too long and causing too much heat?

I still wonder if I should try 220v...but 220v single phase (even though ads for this motor say it's a three phase motor?

It seems like the point of this present arrangement is single phase, right?

I do have single phase available more readily than three at this location (allow electrician to tap in near the water heater instead of near the drier) and I'd have to get help with wiring. I say “single phase” when I really perceive “220v single phase”as two phase, but anyway...

I'm a hack in this area and appreciate the help immensely!

P.S. -- reply to user: Just for Fun in Washington -- thanks for the reply -- Well, the only reason I mentioned the planer was as a reference (as in "If a motor is made to work on either, will it say so?"). I noted the A-OK planer's manufacturer's plate said 220v or 110v, whereas the problem mill's plate says just 220v making me wonder if it wasn't meant for 110v no matter how you wire it. Like maybe it requires inordinate current for a typical 15 amp circuit or something. Maybe you meant look at it to see if the mill is wired the same? That might have helped me learn but I do think the planer is a 1-cap deal. I DO wonder if maybe the guy that had the mill might have done was you say and used a 110v plug and outlet to run 220! I wouldn't bet my life against it! Haha...

update on the mill:

bad start cap for one thing...

...but was it ever good being run on 110v even when it “worked”?

So:

The motor capacitors are:

CD60, 220/265 V.A.C., 150 MFD

(presumably the START cap)

*THIS one tests BAD (meter says 0.F)

- - - -

CBB60 SH, 450 V.A.C., 25 MFD

(presumably the RUN cap)

This tests 23.88 MFD on the outside of within +/- 5% tolerance

* So it's staring to look like the theory of it not having enough oompf and getting to speed?

Question: If it's not getting to speed (and it does seem sluggish starting) then I presume the <click> is not the centrifugal switch successfully tripping but rather, what (?) a thermal breaker (like it sounds) tripping because startup is straining and/or taking too long and causing too much heat?

I still wonder if I should try 220v...but 220v single phase (even though ads for this motor say it's a three phase motor?

It seems like the point of this present arrangement is single phase, right?

I do have single phase available more readily than three at this location (allow electrician to tap in near the water heater instead of near the drier) and I'd have to get help with wiring. I say “single phase” when I really perceive “220v single phase”as two phase, but anyway...

I'm a hack in this area and appreciate the help immensely!

P.S. -- reply to user: Just for Fun in Washington -- thanks for the reply -- Well, the only reason I mentioned the planer was as a reference (as in "If a motor is made to work on either, will it say so?"). I noted the A-OK planer's manufacturer's plate said 220v or 110v, whereas the problem mill's plate says just 220v making me wonder if it wasn't meant for 110v no matter how you wire it. Like maybe it requires inordinate current for a typical 15 amp circuit or something. Maybe you meant look at it to see if the mill is wired the same? That might have helped me learn but I do think the planer is a 1-cap deal. I DO wonder if maybe the guy that had the mill might have done was you say and used a 110v plug and outlet to run 220! I wouldn't bet my life against it! Haha...