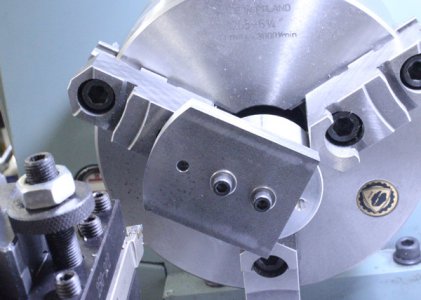

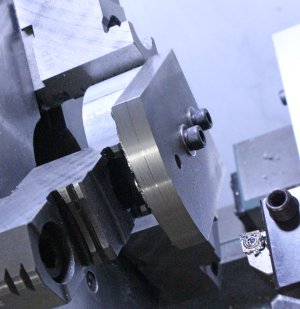

I have a lot internal pocket milling work on the horizon & that can be very tedious chore without some kind of stop to limit travel as you work your way down the material end milling (as opposed to watching dials and/or DRO position at each end of every pass). I made a similar system for my old RF-45 mill & it worked out pretty good. The basic idea is you set the table to desired left position, set the left stop. Then do the same for right. Now when milling you can just traverse the table back & forth until it contacts the stops on either side.

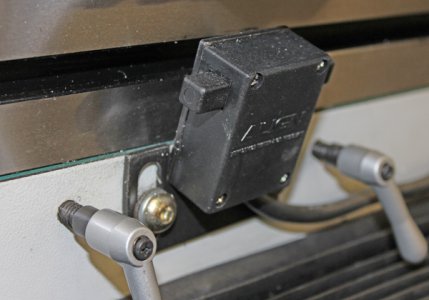

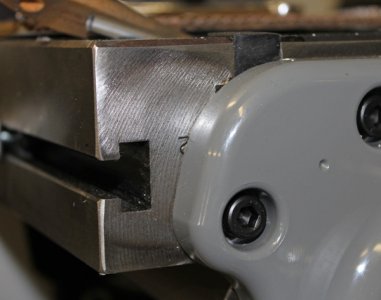

My 935 mill has different dimensions so about all I could use was the concept & materials on hand. I have a power feed on the X so I temporarily removed the limit stop switch, wrapped its cord up neatly & just strapped it to the motor unit so its out of the way. Yes, the electric limit switches work pretty reliably as an e-stop, but I find power feeding short lengths is more of a hassle than its worth. The spring limit bumpers just slide out of the Tee slot along the front of the table. The mill base was already drilled & tapped 5/16 for the center limit switch so I decided to make use of those holes.

My 935 mill has different dimensions so about all I could use was the concept & materials on hand. I have a power feed on the X so I temporarily removed the limit stop switch, wrapped its cord up neatly & just strapped it to the motor unit so its out of the way. Yes, the electric limit switches work pretty reliably as an e-stop, but I find power feeding short lengths is more of a hassle than its worth. The spring limit bumpers just slide out of the Tee slot along the front of the table. The mill base was already drilled & tapped 5/16 for the center limit switch so I decided to make use of those holes.

Attachments

Last edited: