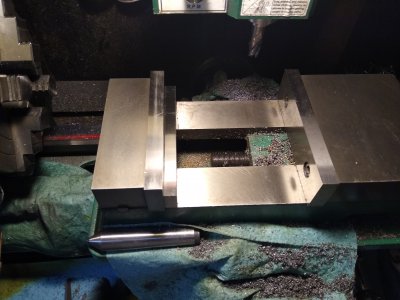

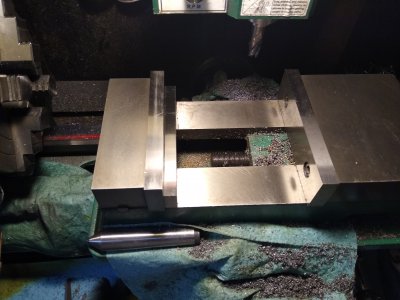

I'll start with a picture.

Swarf, pulled out from the main screw. Swarf, pulled out from under the moving jaw. Swarf in places I don't want it to be. So, I'm thinking of a cover to go over the main screw & a moving dam to go under the moving jaw. I searched for what others may have done & found nothing. Any & all ideas are welcome!

Swarf, pulled out from the main screw. Swarf, pulled out from under the moving jaw. Swarf in places I don't want it to be. So, I'm thinking of a cover to go over the main screw & a moving dam to go under the moving jaw. I searched for what others may have done & found nothing. Any & all ideas are welcome!