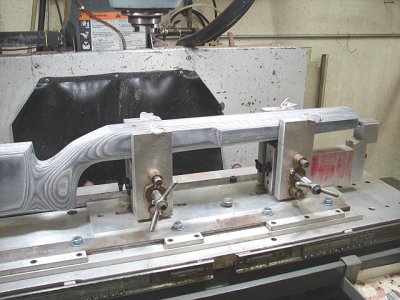

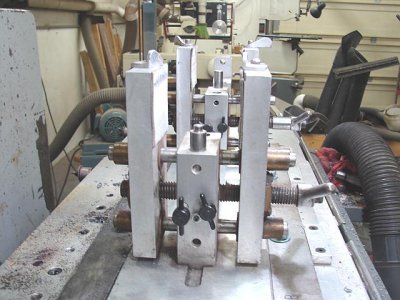

OK,this is a touch "cloodgy" but is dang quick to setup and dial in. Think it's 3" channel? Can measure if you need it.

There's a cpl things that make this worthwhile; cheapness leading the effort. Drill/tap anywhere,and welding on it is easy too.

The opposing jack screws are ridiculously easy to dial in,either centerlines or offsets. There's 1/4" plywood pads that keep the stock off the bttm.... and also are used on the JS (jack screws). The key is to have the JS above the waterline of the stock..... so as you snug them,they also pull/push stock downwards in the fixture.

A surface gage works to set elevation,and by using the pins in the SG base.... the gage will set centerline. I use it with router bits for opening up barrel channels. They've been working fine and are easier(for me) to keep a sharp edge on...and contrary to what folks say about rpm's,have had zero problems running them at VERY low speeds. To the point that in some composites,the slower the better.

I've run a dz or so wood stocks through this fixture(and a BUNCH of plastics)and usually just throw some tape on things to keep from scratching. One nice thing is,the whole fixture pops out and can be moved to a drill press without undo figiting.

Might help someone?

View attachment 404333