Hi everyone,

I have a PM30 I use for milling out stocks and various other machining projects related to custom rifle building.

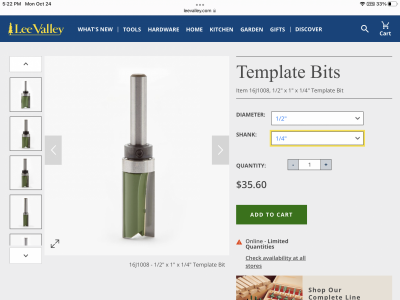

Which brings me to my question-what end mill do I need to remove bedding material (Devcon) all the way into the corners but not remove the material above it?

I’ve attached a picture of the area I’m relieving. I don’t want to enlarge the sides, but I want to mill down the flat area, which means I need to relieve it all the way into the corners.

Thanks in advance!

I have a PM30 I use for milling out stocks and various other machining projects related to custom rifle building.

Which brings me to my question-what end mill do I need to remove bedding material (Devcon) all the way into the corners but not remove the material above it?

I’ve attached a picture of the area I’m relieving. I don’t want to enlarge the sides, but I want to mill down the flat area, which means I need to relieve it all the way into the corners.

Thanks in advance!