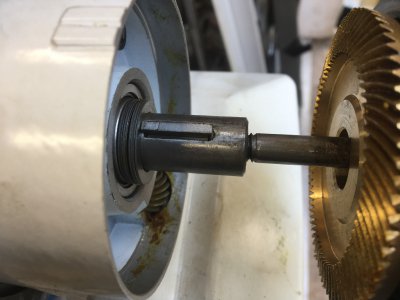

Well, for the last two weeks I’ve been installing a power feed for my Millrite MVI milling machine. I took a number of pics of the install so I’ll document my installation in the next few days. For reference I looked at a couple of instructions on the net, including one on groups.io site and Bob Korves installation on this site.

Bob removed the x-axis lead-screw for his installation and although I too felt this might be the best route in order to drill and install an extension, I thought I could avoid this step by going about it differently. The risk with my method is that there was a chance of ending up with an extension off center. Bobs install shows how he mounted a slightly oversized extension and then turned it true to the shaft on the lathe.

Call me lazy. Take your pick. In all honesty his method is probably best. But I didn’t want to go through that much trouble. So I’ll soon be posting some pics and showing how I went about it.

Bob removed the x-axis lead-screw for his installation and although I too felt this might be the best route in order to drill and install an extension, I thought I could avoid this step by going about it differently. The risk with my method is that there was a chance of ending up with an extension off center. Bobs install shows how he mounted a slightly oversized extension and then turned it true to the shaft on the lathe.

Call me lazy. Take your pick. In all honesty his method is probably best. But I didn’t want to go through that much trouble. So I’ll soon be posting some pics and showing how I went about it.

Last edited: