Hello,

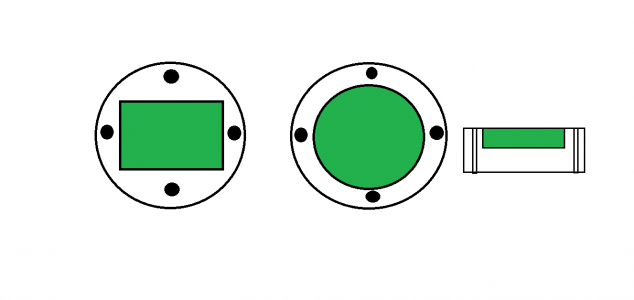

This is my second post so don't be too hard on me. I've been doing a bunch of reading on Mini Mills, but still don't know if it will do what I need and what cost I'm getting into. As of right now I'm looking to mill some under water light housings for my boat. The housings could be made out of Aluminum or Bronze. What I'm looking to do is mill a pocked 1/4" deep out of a 4"x1" round puck. The machines I'm looking at start at around $500 from Harbor Freight then I'm reading that I need like $500 worth of add ons?? What if the cheapest route I can go to get a job like this done? where should I start looking? There are a ton of different bits ect... What tools would I need to complete this project? If I'm looking at big $$$ I may just have to hold off.

Thank You

This is my second post so don't be too hard on me. I've been doing a bunch of reading on Mini Mills, but still don't know if it will do what I need and what cost I'm getting into. As of right now I'm looking to mill some under water light housings for my boat. The housings could be made out of Aluminum or Bronze. What I'm looking to do is mill a pocked 1/4" deep out of a 4"x1" round puck. The machines I'm looking at start at around $500 from Harbor Freight then I'm reading that I need like $500 worth of add ons?? What if the cheapest route I can go to get a job like this done? where should I start looking? There are a ton of different bits ect... What tools would I need to complete this project? If I'm looking at big $$$ I may just have to hold off.

Thank You