- Joined

- Sep 6, 2013

- Messages

- 8

My lathe has a broken worm-wheel gear for the power feed, and is also missing a gear and a shaft inside the apron.

It's a Jet 1024P (10") lathe, made in Taiwan in the 1980s (I think). I got it used from a factory that was closing, no information is available from the source. The manufacturer does not have any information, but I did find a couple of PDFs for the manual searching online - neither is exactly my machine, but close in most areas except the apron.

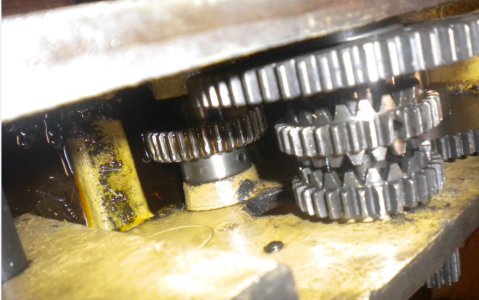

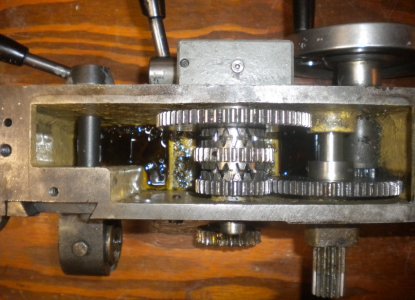

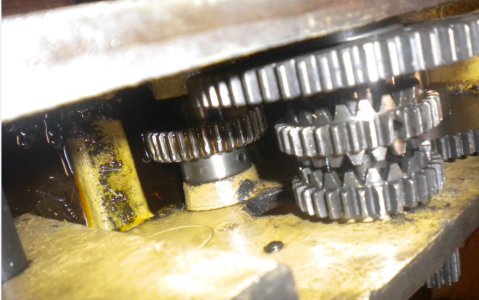

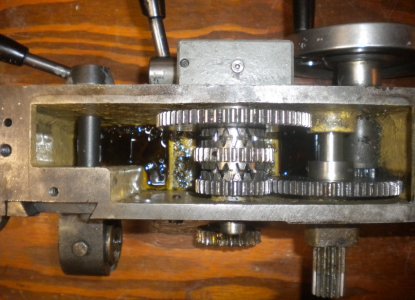

I'm not terribly worried about the brass worm wheel gear; fixing or replacing / making a replacement isn't too bad when you have the original part in hand. But the missing parts have been a show stopper. Best I can tell, it was some kind of idler gear and shaft (mounted between the lower shaft that's connected to the worm, and the clutch power feed gears - notice the space and hole in this area in the attached photos).

The parts diagrams from the manuals I've looked at don't show this assembly. It appears that the worm wheel gear shaft on mine is mounted much lower than others, resulting in a large gap - where an idler probably existed.

One thing that's really confused me here is that all of the other shafts have substantial support on both ends, yet the idler is supported on one end only without any shoulder from the casting (the casting wall is at its thinnest in this area). It appears like a design flaw on my model, that the other manuals show corrected (by moving all the worm parts up so the drive gear contacts the clutch gear).

I'd appreciate hearing anything helpful that you may think of.

Bruce.

It's a Jet 1024P (10") lathe, made in Taiwan in the 1980s (I think). I got it used from a factory that was closing, no information is available from the source. The manufacturer does not have any information, but I did find a couple of PDFs for the manual searching online - neither is exactly my machine, but close in most areas except the apron.

I'm not terribly worried about the brass worm wheel gear; fixing or replacing / making a replacement isn't too bad when you have the original part in hand. But the missing parts have been a show stopper. Best I can tell, it was some kind of idler gear and shaft (mounted between the lower shaft that's connected to the worm, and the clutch power feed gears - notice the space and hole in this area in the attached photos).

The parts diagrams from the manuals I've looked at don't show this assembly. It appears that the worm wheel gear shaft on mine is mounted much lower than others, resulting in a large gap - where an idler probably existed.

One thing that's really confused me here is that all of the other shafts have substantial support on both ends, yet the idler is supported on one end only without any shoulder from the casting (the casting wall is at its thinnest in this area). It appears like a design flaw on my model, that the other manuals show corrected (by moving all the worm parts up so the drive gear contacts the clutch gear).

I'd appreciate hearing anything helpful that you may think of.

Bruce.