- Joined

- Nov 16, 2012

- Messages

- 5,596

Ok... Planning to do this in a few parts and am writing this as I go. The goal is to show the nitty-gritty basics about a miter gear and how to make one with a standard involute tooth surface. The intention is for folks to understand enough so when they open Machinery's Handbook and open the section on gears, you can follow along and then advance to more complicated gear types.

The tutorial on basic spur gears has most of the basic definitions and it's best to read that first before digging into this. https://www.hobby-machinist.com/threads/cutting-gears-diametral.69653/#post-584129 The format of this will be the about the same... A few "classroom lessons" with definitions and terms, followed by actually making the gear. I won't be able to start making the gear for a few days due to my FT job getting in the way of fun.

Part 1 ....

A miter gear is a special case of bevel gear. A miter gear connects shafts that are at right angles. A bevel gear can connect shafts at arbitrary angles (but there are some practical limitations).

FYI: For this example, we're talking about straight-tooth gears. The configuration of the teeth (curved etc) does not change the fact that the gear is a bevel-type gear.

A pair of mating miter gears can be different sizes but must be the same diametral pitch (for US sized gears) or modulus (for metric gears). This rule is true for all types of gears.

Diametral Pitch has the same meaning as for spur gears. If the gear is defined to be a 16 DP gear then, for every inch of diameter there will be 16 teeth. As diameter increases tooth count increases according to that ratio.

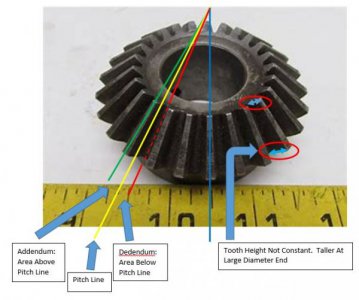

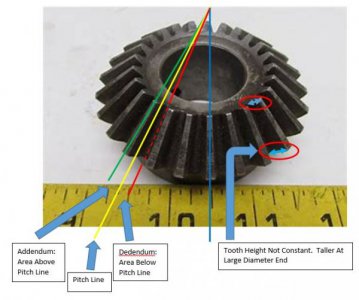

See the basic picture of the major features.

The yellow line is the Pitch Line. Since miter gears connect intersecting shafts, the Pitch Line of a miter gear is 45 degrees. The Pitch Line is with respect to the blue line which is the centerline of the gear and/or axis of the shaft. The Pitch Line does not correspond to any physical feature of the gear. Even though this could be called a 45 degree gear, there is no physical component that is 45 degrees.

The green line (surface line) is on top of the surface of the Addendum. The angle with respect to the pitch line is the "Addendum Angle" and everything above the yellow line up to the green line is the "Addendum" part of the tooth. The Addendum angle is usually a few degrees (we will calculate it later). The metal gear blank must have a "Surface Angle" that equals the pitch angle (45 degrees) plus the Addendum angle.

The red line is the "Cut Line" and rides at the bottom of the tooth. The angle between the pitch line and the cut line is called the Dedendum angle. This angle is not numerically the same as the Addendum angle. The milling cut angle will be "45 degrees minus the Dedendum angle".

Notice that all the lines intersect at an imaginary point at the top of the gear. The physical characteristics (defined by the surface and cut lines) have different angles. As a result of this, the tooth depth of a miter gear is not constant along its length. Look a the red circles and you can see tooth depth is different from top to bottom. The term tooth depth and "Whole Depth" will come-up later so be apprised, when measured, it is the depth at the deepest end of the tooth.

Some definitions for Part 1:

Just like with the spur gear, the Addendum = 1 / Diametral Pitch. This is physically measured from the pitch line to the top of the tooth at the tallest part of the tooth (at the OD of the gear).

The Dedendum for bevel gears depends on which standards the gear is being made to. There are multiple variations and usually, gears made by different standards should still mesh but, the clearance at the root and addendum might not be suitable for a given application. In this example the dedendum is being assumed to be the classic model shown in Machinery Handbook. Dedendum = 1.157 / Diametral Pitch. This is measured from the pitch line at the tallest part of the tooth (at the OD of the gear).

If you stick to this standard (which is recommended when milling gears manually) the Whole Depth = 2.157/ Diametric Pitch or Whole Depth = Addendum + Dedendum. The values will come out the same if you stick with this convention.

Almost all of the physical features are now defined. Next, we will define a few intermediate terms that help make the math easier. After that, we'll show formulas to determine everything you need to make a gear. That is: the "Cutting Angle", "Stock Surface Angle", "Whole Depth", "Outside Diameter" and something called "Virtual Teeth" (which is used to determine which cutting gear to use).

Until we meet again...

Ray

The tutorial on basic spur gears has most of the basic definitions and it's best to read that first before digging into this. https://www.hobby-machinist.com/threads/cutting-gears-diametral.69653/#post-584129 The format of this will be the about the same... A few "classroom lessons" with definitions and terms, followed by actually making the gear. I won't be able to start making the gear for a few days due to my FT job getting in the way of fun.

Part 1 ....

A miter gear is a special case of bevel gear. A miter gear connects shafts that are at right angles. A bevel gear can connect shafts at arbitrary angles (but there are some practical limitations).

FYI: For this example, we're talking about straight-tooth gears. The configuration of the teeth (curved etc) does not change the fact that the gear is a bevel-type gear.

A pair of mating miter gears can be different sizes but must be the same diametral pitch (for US sized gears) or modulus (for metric gears). This rule is true for all types of gears.

Diametral Pitch has the same meaning as for spur gears. If the gear is defined to be a 16 DP gear then, for every inch of diameter there will be 16 teeth. As diameter increases tooth count increases according to that ratio.

See the basic picture of the major features.

The yellow line is the Pitch Line. Since miter gears connect intersecting shafts, the Pitch Line of a miter gear is 45 degrees. The Pitch Line is with respect to the blue line which is the centerline of the gear and/or axis of the shaft. The Pitch Line does not correspond to any physical feature of the gear. Even though this could be called a 45 degree gear, there is no physical component that is 45 degrees.

The green line (surface line) is on top of the surface of the Addendum. The angle with respect to the pitch line is the "Addendum Angle" and everything above the yellow line up to the green line is the "Addendum" part of the tooth. The Addendum angle is usually a few degrees (we will calculate it later). The metal gear blank must have a "Surface Angle" that equals the pitch angle (45 degrees) plus the Addendum angle.

The red line is the "Cut Line" and rides at the bottom of the tooth. The angle between the pitch line and the cut line is called the Dedendum angle. This angle is not numerically the same as the Addendum angle. The milling cut angle will be "45 degrees minus the Dedendum angle".

Notice that all the lines intersect at an imaginary point at the top of the gear. The physical characteristics (defined by the surface and cut lines) have different angles. As a result of this, the tooth depth of a miter gear is not constant along its length. Look a the red circles and you can see tooth depth is different from top to bottom. The term tooth depth and "Whole Depth" will come-up later so be apprised, when measured, it is the depth at the deepest end of the tooth.

Some definitions for Part 1:

Just like with the spur gear, the Addendum = 1 / Diametral Pitch. This is physically measured from the pitch line to the top of the tooth at the tallest part of the tooth (at the OD of the gear).

The Dedendum for bevel gears depends on which standards the gear is being made to. There are multiple variations and usually, gears made by different standards should still mesh but, the clearance at the root and addendum might not be suitable for a given application. In this example the dedendum is being assumed to be the classic model shown in Machinery Handbook. Dedendum = 1.157 / Diametral Pitch. This is measured from the pitch line at the tallest part of the tooth (at the OD of the gear).

If you stick to this standard (which is recommended when milling gears manually) the Whole Depth = 2.157/ Diametric Pitch or Whole Depth = Addendum + Dedendum. The values will come out the same if you stick with this convention.

Almost all of the physical features are now defined. Next, we will define a few intermediate terms that help make the math easier. After that, we'll show formulas to determine everything you need to make a gear. That is: the "Cutting Angle", "Stock Surface Angle", "Whole Depth", "Outside Diameter" and something called "Virtual Teeth" (which is used to determine which cutting gear to use).

Until we meet again...

Ray