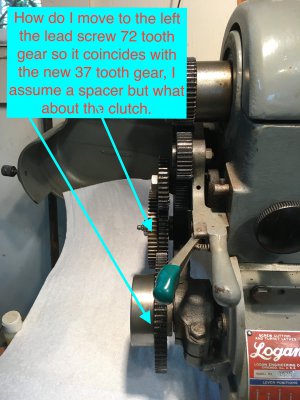

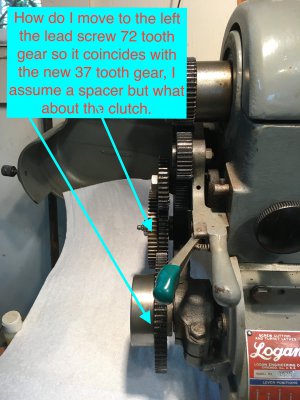

I'm looking at a photo of the transposing gears from a later Logan-Powermatic catalog. It shows the gear on the lead screw engaging

the smaller gear to the outside (37T). The gear on the lead screw is attached to the shaft with no clutch shown. I wonder if the clutch

needs to be removed and the gear bolted directly to the shaft?

Sorry, I can't find a way to post the photo: it's part of a large PDF which is too big to post to the thread. If you contribute to the site,

you can look in Downloads at the 1980 Logan Catalog and you'll see it.

Hello all, I'm new here, this is my first post ... Metric Threading Conversion for the Logan Lathe ...

I am also adapting my Logan Model 1957 QC lathe to cut metric threads, after many years of languishing over the project ... Years ago I obtained the new/spare change gears needed from Dave Sobel (Closter, NJ) and Boston Gear, 20+ years ago now; (two 60T's, 37T, 42, 47,48 and a 54 tooth) 16 pitch, 5/8" bore, 5/32" key-way gears) ...there are 39T and 66T stud gears 'called out' on the Logan chart, but are for odd-ball metric pitches I'll prolly never need anyway, so I don't need those gears .... The Logan Metric chart is available on-line.

This chart shows the ISO standard metric pitches as asterisked, so my gears, as listed above, cover those.

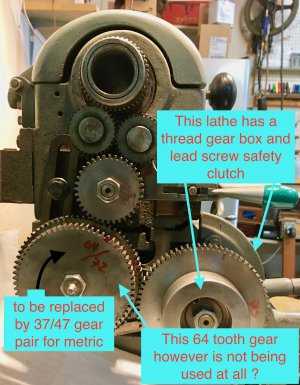

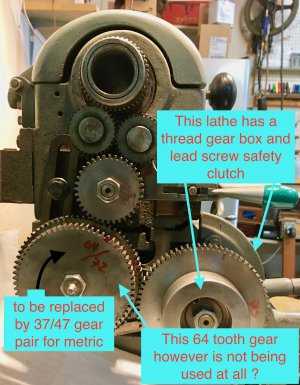

My lathe came from a school, and had the optional Logan LA-774-1 'Automatic Safety Gear' (safety clutch) installed on the leadscrew (like in the photo from originating post), so in case of a crash by the kids, any damage would be minimal! This assembly has a solid steel 72T gear as an integral part of the safety clutch assembly.

This safety clutch is removed from the leadscrew by removing the 3/4" nut with a socket, and the clutch/72T screw-gear assembly will slide right off... be careful not to lose the small woodruff key!

The metric transposing gear-pack assy (47/37T gears keyed together on a bushing) requires that the new 60T 'screw gear' to be spaced out on the end of the lead-screw, to mesh properly with the 37T transposing gear. Two spacer washers need to be machined to achieve the proper gear-face spacing, with a 5/8" bore, one washer with a keyway and the other plain, to properly space the gears. Use the plain spacer washer (approx 1/8" thick by 1-1/8" dia. ?) first against the gearbox, then a spare new unused change gear against the QC gearbox, then the woodruff key and then slide on the new 60T screw gear and snug-up the 3/4" nut. The safety clutch/72T assy is not used to cut metric threads, but will be re-installed to return to SAE threading. I plan on machining the two new 'screw-gear' spacer washers from cast-iron barstock.

I ordered a new change gear bushing (LA-231) and 5/32" key (LA-249) from Logan Actuator Co. to assemble the 47/37 transposing gear pack, to keep it together for convenience, rather than dis-assembling the std. 64/72T pack assy that came as std. with the lathe. A new thin spacer washer may need to be machined to space the transposing gears on the new bushing (I'm awaiting parts from Logan now).

Some of my new change gears came from Boston Gear; these come std. with a 3/4" bore and double 3/16" keyways, so unusable as-is.... I'll bore-out these gears, and re-bush. I'll machine new bushings from 1-1/4" dia. cast iron barstock, bore/ream 5/8" and cut the required 5/32 keyways in the new 47 and 37 and 42T (stud) Boston gear bushings. Then press-in/Loctite the new bushings into those three gears. The other change gears are original NOS Logan gears that Dave S. had....

I know, this is a longish first post, so I apologize!! But maybe it can help someone out here.... If I run into any snags with this project, I will advise on this thread as I go along.

John B.