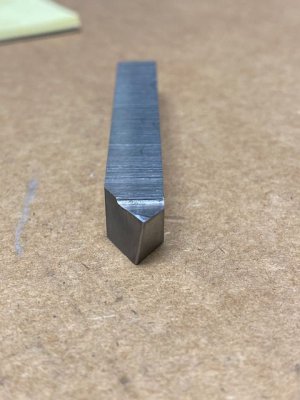

Yes Mikey i am talking about a form tool. I just finished these tools up tonight. A 45 and a - threading tool that i modified to just be a chamfering tool.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Models for grinding HSS Lathe Tools

- Thread starter mikey

- Start date

- Joined

- Mar 26, 2018

- Messages

- 8,407

- Joined

- Dec 20, 2012

- Messages

- 9,422

I thought I had the perfect grind. What's wrong with it?

The correct answer is worth 5 points!!

Hint, it doesn't leave a very good finish on 12L14!

Glad to see you taking a shot at this, Jeff!

You asked so I'm going to be honest and tell you what I think. Then we are going to fix it so that it works really well, okay?

It's really hard from me to tell but it looks like you might have decent relief angles under the edges. However, you have essentially no rake angles, which means you are trying to turn steel with a zero rake turning tool. It will work with brass but it will not turn steel well at all. To fix this, you need to grind some side and back rake into the top surface of the tool.

Go to this thread and scroll down until you hit a subheading called "The Top". Have a look at how I set up the rake grinds and give that a try. Once you have the rake angles correct, stone a nose radius on the tool and try turning that 12L14 again. If you would, please post pics again so we can see your progress. Have a look at the way I took the pictures in that thread and duplicate them so we can see the angles you're grinding.

I also suggest you PM @Z2V and get ahold of the model tools he has. It will give you a better idea of what a turning tool looks like.

Stick with it, Jeff, and I will stick with you until we get it right.

- Joined

- Mar 26, 2018

- Messages

- 8,407

That's it!some side and back rake into the top surface of the tool.

I got all done with this, tried it out with poor results. I then noticed the top was flat!

Works great on brass with a slow feed.

I'll post after I regrind. Try it out.....

- Joined

- Mar 26, 2018

- Messages

- 8,407

Much better. The radius and side rake helped a bunch. The tool is sharp!

Attachments

-

6C55FA7E-1B1E-4E07-A9AB-A943136ED4EC.jpeg745.3 KB · Views: 19

6C55FA7E-1B1E-4E07-A9AB-A943136ED4EC.jpeg745.3 KB · Views: 19 -

531CF2AB-1DBA-4FC7-8081-3658116ADD3A.jpeg1.2 MB · Views: 20

531CF2AB-1DBA-4FC7-8081-3658116ADD3A.jpeg1.2 MB · Views: 20 -

B75DF8D2-EEC5-46B2-A5A5-6D5628E43543.jpeg1.2 MB · Views: 22

B75DF8D2-EEC5-46B2-A5A5-6D5628E43543.jpeg1.2 MB · Views: 22 -

5778D42C-CE60-472F-A934-F113077BA77A.jpeg1.3 MB · Views: 24

5778D42C-CE60-472F-A934-F113077BA77A.jpeg1.3 MB · Views: 24 -

86DC9EBA-4699-46A4-B53E-7A55BFE33F9D.jpeg1.2 MB · Views: 25

86DC9EBA-4699-46A4-B53E-7A55BFE33F9D.jpeg1.2 MB · Views: 25 -

3D3F984F-89B8-4114-A1EF-6164B1662ECA.jpeg1.5 MB · Views: 26

3D3F984F-89B8-4114-A1EF-6164B1662ECA.jpeg1.5 MB · Views: 26 -

3AA61A46-5111-4E79-BFF3-BF08EF601298.jpeg1.2 MB · Views: 25

3AA61A46-5111-4E79-BFF3-BF08EF601298.jpeg1.2 MB · Views: 25 -

B61C6581-6349-48D0-A5E8-0229A900C26C.jpeg2 MB · Views: 21

B61C6581-6349-48D0-A5E8-0229A900C26C.jpeg2 MB · Views: 21

- Joined

- Dec 20, 2012

- Messages

- 9,422

Better, Jeff. I can see some side and back rake now. The nose radius is too large and your edges are NOT sharp. If you look at the shot with the top view, you can see light reflecting off the cutting edge. That means the top is not flat all the way to the cutting edge. In 12L14, a good tool will produce almost a mirror finish. I would hone all three faces to get then dead flat and then the tool will cut as it should.

- Joined

- Mar 26, 2018

- Messages

- 8,407

Easier said than done pal.Better, Jeff. I can see some side and back rake now. The nose radius is too large and your edges are NOT sharp. If you look at the shot with the top view, you can see light reflecting off the cutting edge. That means the top is not flat all the way to the cutting edge. In 12L14, a good tool will produce almost a mirror finish. I would hone all three faces to get then dead flat and then the tool will cut as it should.

I’m really struggling keeping the stone from wandering and screwing up my edge.

I have several stones to choose from.

I’m going to try my new lapping machine

thank you for your help!

Grinding HSS is easy, just like golf

- Joined

- Oct 4, 2016

- Messages

- 7,012

It's muscle memory, tricky at first, when your fingers start learning how to respond to what your eyes are seeing it will be much better. I'm using diamond lapping plates, and getting more comfortable with it.