- Joined

- Dec 18, 2019

- Messages

- 6,437

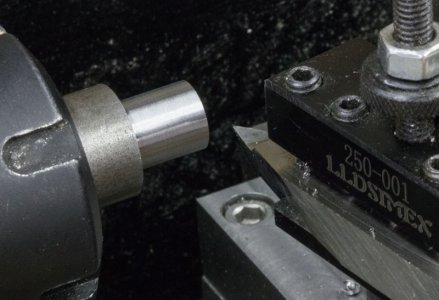

@Janderso page 10, post #104 gives you the directions you need. @mikey's write up is amazing. He has great pictures, and clear instructions. This thread has greatly increased in size since that time, so you may have missed it. As stated very early in this thread, practice with cheap keystock. I know it helped me a lot to get the basic shapes right. Wish the honing was easier for me, but, I'm still working on that. Need to build a nice low speed grinder like yours!