- Joined

- Dec 18, 2019

- Messages

- 6,438

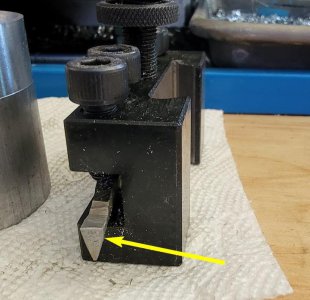

I would think a rounded edge might not give enough relief on the outside edge, but truly, I'm just a beginner at this. I defer to others with far more experience. The tool was good enough for what I needed to do. Could it be made better? Very likely. First time trepanning was unsettling, to say the least. Once the edges were sharp and had sufficient relief, had no troubles.