- Joined

- Jan 16, 2017

- Messages

- 216

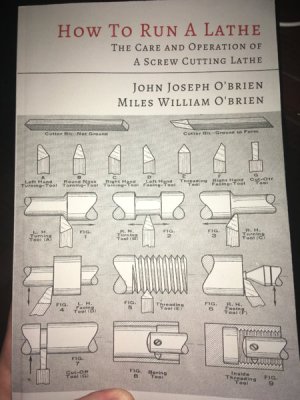

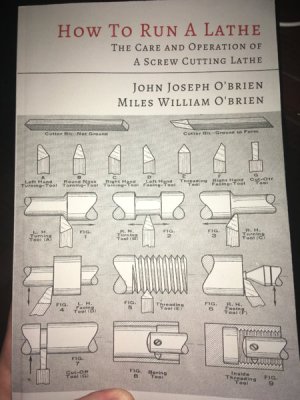

Wow this thread really kicked off. Is there a pic with all the models included? I forgot I actually had this great book on lathe tooling and function.

I highly recommend this book for anyone getting into lathes. It has numerous ways to ground tool bits for the lathes and some very good educational material for threads and other things. Great book for referencing.

I highly recommend this book for anyone getting into lathes. It has numerous ways to ground tool bits for the lathes and some very good educational material for threads and other things. Great book for referencing.

Last edited: