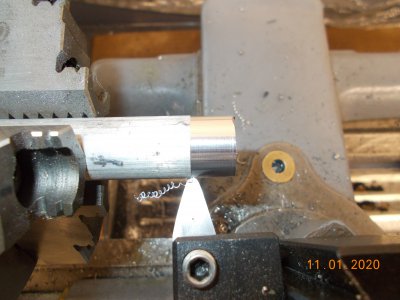

First cut on aluminum with the tool I ground a couple months ago.

and I am pleased with the results

Use the same tool to finish the chuck key for the bison I bought a while back as well.

I meant to get back and respond to this post but life is truly hectic of late. My apologies.

For those of you who have not seen a tool like this before, it is called a Round Nose tool. It is characterized by the round nose radius, essentially identical side cutting edge profile on either side and typically has zero top rake. It is able to cut in either direction, which is helpful if you have to cut a section between two shoulders or collars. Due to the relatively large nose radius, a Round Nose tool tends to finish okay but it cannot take huge cuts without chattering. This is because the nose radius generates a lot of radial cutting forces. When compared to a general purpose turning tool, it is not capable of deeper cuts because of this.

In order for this tool to finish well you must do one of two things: slow the feed considerably or it will inscribe fine lines OR you can create a much smaller nose radius and alter your lead angle and use the edges just back/adjacent to the nose radius. This latter method will finish much, much better for you. Typically, I use a parting tool to make two adjacent cuts to create the shoulders on each side of the section being turned, then angle the tool so I am cutting with an edge instead of the nose. The finish is usually much better and because the edge cuts more accurately, it is easier to come in on size with this method.

For those of you who have not tried this tool in brass, you are in for a treat. This tool will put a mirror finish on brass with almost no effort. Due to its versatility, this is a tool that is worth grinding. I suggest 15 degree side relief angles. Keep the nose radius small, about 1/32" will do. If you plan to use this tool strictly on brass, try grinding about 5-7 degrees of back rake on top; you will be very pleased at how well this tool cuts when modified this way. For use in other materials, use zero rake on top.