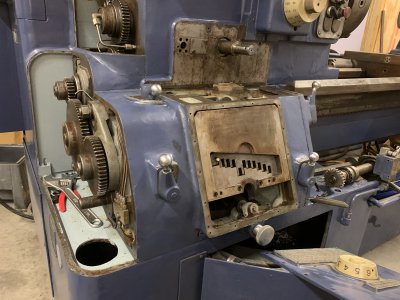

The QCGB is back on, headstock end pretty much buttoned up.

I was test running it after that and at 1500 RPM the 30A breaker popped. No load. I suspect I will need to do some balancing on my RPC. Need to install the volt-amp meters on the RPC ... I'll also replace the 30A with a 40A.

Of course, there is quite a bit more work to do on this before it is a functional lathe. The apron is still not installed. While it is off I want to flush it out, clean off the outside, and remove the oil pump for cleaning and new filters. The apron alone on this beast (not the full carriage), probably weighs 400 lbs, almost as much as my first 10x22 lathe.

Along the way the apron and carriage will get painted blue to match the rest of the lathe. I'll need to pull the cover off the QCGB to put the threading leadscrew back on. It has 4 shafts on the apron, threading leadscrew, feed rod, rapid traverse drive rod, and clutch control. I put the clutch rod back in temporarily to test the headstock/QCGB. Just a taper pin at the QCGB end, and a bushing that slides into the support at the tailstock end.

Putting the cart before the horse, I'm thinking about a QCTP for this, as well as a 4 jaw chuck.

It is close to 3" from compound base to centerline, so I'll need a DA sized toolpost. $$$

I'd like to get a forged steel 4 jaw 16" chuck. (612-2516, 25" swing, 16" over the carriage). More $$$

Probably be looking on ebay for used(?).