- Joined

- Jul 26, 2013

- Messages

- 584

Hello all,

I bought this lathe today which turns out to be a South bend clone of a 9" lathe. It's an awful dirty looking mess at the moment, but I think that it will clean up nicely. It didn't come with much, but the original bracket and cone pulley drive is intact ( removed for moving ) and it came with a 4-jaw chuck and steady rest as well as a threading dial and change gears.

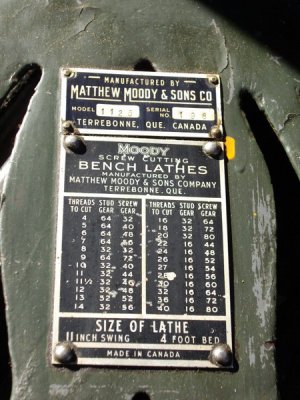

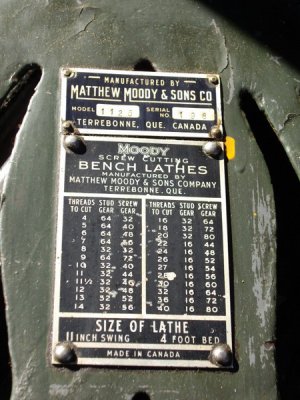

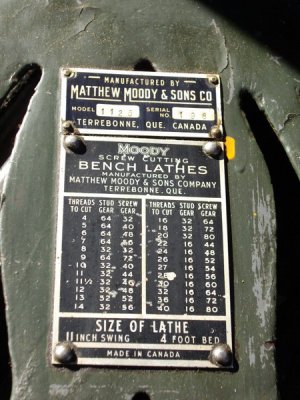

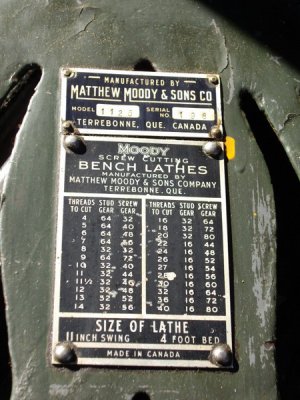

It was manufactured by Matthew Moody and sons in Terribone Quebec, but I have no idea of how early it is. The serial number is #198 and the model number is #1125.

Here's a few pics...

The former owner and son in the background and my brother with his head chopped off...

![URL]](/proxy.php?image=http%3A%2F%2F%5BURL%5Dhttp%3A%2F%2Fi1199.photobucket.com%2Falbums%2Faa468%2FRambaudiLSR%2FIMGP0513800x600_zpsa33090b4.jpg%5B%2FURL%5D&hash=5f70e774f90abbe3a591db55cf8f12df)

As you can see by the threading chart, this lathe has an 11" swing. It also looks like it has a 1" spindle hole. I have already begun dismantling the lathe and have managed to remove the apron, cross-slide, top slide and saddle. I could see that there was a definate "frosting on the ways and after some cleaning with mineral spirits, I am happy to note that nearly all of the frosting is like new, with little wear near the head-stock. I believe that this lathe is fairly old but the threading chart doesn't look to be all that old.

If any of you out there have a Moody lathe, I'd like to hear about yours. There seems to be very little info on these lathes.

I am having some difficulty in dismantling the top slide. Any of you who have a 9" South Bend and have taken it apart might be able to help me.

Here's a pic...

I can remove the nut, the ball crank, the micrometer dial, but I can't get any further. I assume that the last bit with the line to zero out the micrometer dial can be removed and then the feed scew and nut can be removed.

Any assistance will be greatly appreciated.

Cheers....

Brian

I bought this lathe today which turns out to be a South bend clone of a 9" lathe. It's an awful dirty looking mess at the moment, but I think that it will clean up nicely. It didn't come with much, but the original bracket and cone pulley drive is intact ( removed for moving ) and it came with a 4-jaw chuck and steady rest as well as a threading dial and change gears.

It was manufactured by Matthew Moody and sons in Terribone Quebec, but I have no idea of how early it is. The serial number is #198 and the model number is #1125.

Here's a few pics...

The former owner and son in the background and my brother with his head chopped off...

![URL]](/proxy.php?image=http%3A%2F%2F%5BURL%5Dhttp%3A%2F%2Fi1199.photobucket.com%2Falbums%2Faa468%2FRambaudiLSR%2FIMGP0513800x600_zpsa33090b4.jpg%5B%2FURL%5D&hash=5f70e774f90abbe3a591db55cf8f12df)

As you can see by the threading chart, this lathe has an 11" swing. It also looks like it has a 1" spindle hole. I have already begun dismantling the lathe and have managed to remove the apron, cross-slide, top slide and saddle. I could see that there was a definate "frosting on the ways and after some cleaning with mineral spirits, I am happy to note that nearly all of the frosting is like new, with little wear near the head-stock. I believe that this lathe is fairly old but the threading chart doesn't look to be all that old.

If any of you out there have a Moody lathe, I'd like to hear about yours. There seems to be very little info on these lathes.

I am having some difficulty in dismantling the top slide. Any of you who have a 9" South Bend and have taken it apart might be able to help me.

Here's a pic...

I can remove the nut, the ball crank, the micrometer dial, but I can't get any further. I assume that the last bit with the line to zero out the micrometer dial can be removed and then the feed scew and nut can be removed.

Any assistance will be greatly appreciated.

Cheers....

Brian