- Joined

- Mar 10, 2012

- Messages

- 1,368

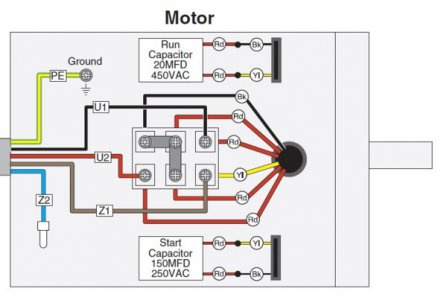

Guys, I need some help here please. My G4003G lathe's motor started slowing down while taking a really light cut the other day. Yesterday I go to start the motor at the 1400rpm setting and it wouldn't spin up unless I helped it. I spins up fine on slower settings tho. I'm thinking it could be either both start and run caps going bad or the motor itself. The motor seems to run and sound fine so I'm hoping it's the caps. The start cap is the one I'm unsure which to go with. The start cap is 150uF, 250V. McMaster has two ranged caps that might work, this 130-156uF cap, and this 145-174uF cap. I don't know which is the better bet to go with. Thanks.