Actually that doesn't help much at all, but perhaps you misunderstood the question so I will define it a bit more.

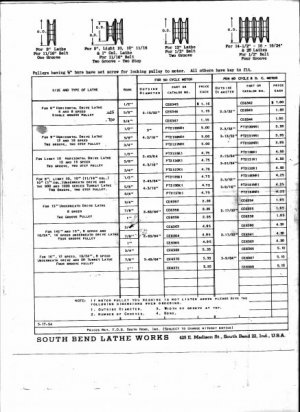

The original set up uses 2 flat pulleys (9.125" and 9.940") on the countershaft, and 2 V pulleys on the motor shaft (size unknown at this time) to create a high and low primary speed to the cone pulleys. The diameter of the sheaves on the motor pulley correspond to the diameters on the flat pulleys so the same belt length works on both.

Something a lot of guys are confused about, is why are there flat pulleys on the counter shaft and V pulleys on the motor? It's very simple. By using flat pulleys on the countershaft, One can roll the belt off and change to the other set of pulleys without adjusting or moving the motor. Something that cannot be done easily using 2 V pulleys.

So, with that explanation, what I'm looking for is the diameter of the sheaves on the motor pulley that correspond with the sizes of the flat pulleys. There is no doubt a factory standard that was used on this model. I know over the years these old machines have been re-motored, rebuilt and revamped to the point some do not have the original pulleys, but it would be nice to know exactly what they came with.