- Joined

- Jan 28, 2020

- Messages

- 193

After I received my Sherline 4400 lathe, I endeavored to follow Sherline's instructions to mount the lathe on a 10" x 36" laminated wood shelf. I was undecided on the color, and purchased one of each from a hardware store: black, white, gray, and brown. I did not find any of them aesthetically pleasing. I returned them.

I searched the forums here for discussions on mounting a Sherline lathe. I found two threads.

https://www.hobby-machinist.com/threads/steel-plate-for-sherline-lathe-base.37437/

https://www.hobby-machinist.com/threads/mounting-small-machine-tools.62194/

The suggestion that I liked best in the discussions was to mount the lathe on extruded rectangular aluminum tubing.

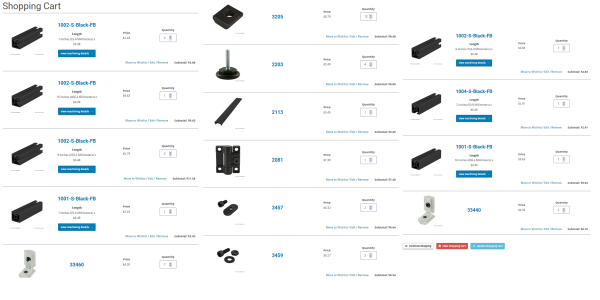

I decided to mount the lathe on frame made from 80/20 T-slot aluminum. This photo shows the result.

There are 2"-wide steel bars along the front and the back of the lathe, for my magnetic dial indicator holder. The four feet are height adjustable. The DRO display is mounted to a hinge with adjustable resistance.

I purchased and used a Starrett model-98 6-inch machinists' level to level the frame, and then to shim the lathe level.

Karl

I searched the forums here for discussions on mounting a Sherline lathe. I found two threads.

https://www.hobby-machinist.com/threads/steel-plate-for-sherline-lathe-base.37437/

https://www.hobby-machinist.com/threads/mounting-small-machine-tools.62194/

The suggestion that I liked best in the discussions was to mount the lathe on extruded rectangular aluminum tubing.

I decided to mount the lathe on frame made from 80/20 T-slot aluminum. This photo shows the result.

There are 2"-wide steel bars along the front and the back of the lathe, for my magnetic dial indicator holder. The four feet are height adjustable. The DRO display is mounted to a hinge with adjustable resistance.

I purchased and used a Starrett model-98 6-inch machinists' level to level the frame, and then to shim the lathe level.

Karl