- Joined

- Dec 31, 2010

- Messages

- 937

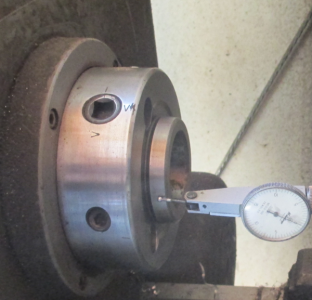

I have an Enco 13 X 40 lathe that hasn't seen much service and I just discovered a problem with the 3 jaw chuck that came with the lathe. I am a newby when it comes to cam lock chucks, so I didn.t pay much attention when uncrating and getting it level; the 4 jaw seems to be OK. Will check that further when it cools off this evening. (Most of my work has been between centers or 4 jaw) but when using the 3 jaw to turn down some 1" mystery metal stock the chuck came loose in the cam lock mechanism. I got it shut down without any major mishap. I checked the clearance between the chuck back plate and the camlock assembly and found the chuck will pull tight to the cam lock assembly on one lock pin but leaves about a 0.010 gap on another lock pin, actually, I believe the taper is to deep in the chuck. It is a straight back chuck so the only place to get more clearance is by facing the cam lock assembly. I did check the cam lock face. the taper on the end of the spindle and the end of spindle with a dial indicator and got less than 0.001 run out on the three surfaces.

I would certainly appreciate comments from anyone that has overcome this problem. Ican;t at this time buy a new lathe.

Ray

I would certainly appreciate comments from anyone that has overcome this problem. Ican;t at this time buy a new lathe.

Ray

It was cheap.

It was cheap.