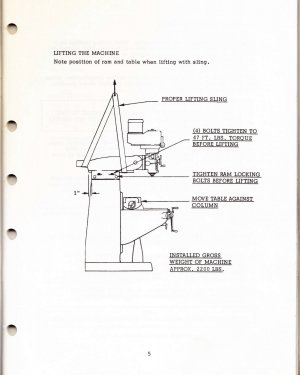

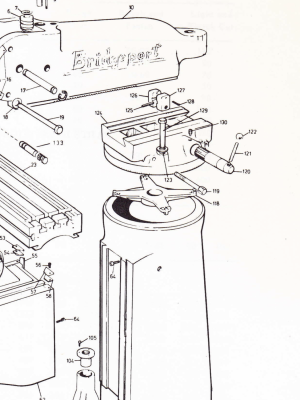

Here is a picture from BP series 1 manual. People have said that the ram dovetails carry the load. Of more concern, should be the cast iron cross, (p/n 118), that the four turret locking bolts thread into, which holds the ram on, is intact IMHO. The four tabs are only about 5/16” or less thick. The last BP that I picked up for my son, we made a castered dolly with built-in leveling screws so that he could roll it into and out of his horse trailer on the beefed up ramp that he made. The dolly is sort of like the one pictured here, but improved.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Moving this machine

- Thread starter snoopdog

- Start date

I unloaded my 9x49 Jet VS mill from a semi-tailer and into my shop with a 5,000# rated forklift, nylon strap through the lifting eye on the ram. Moved the ram for good balance point. About 2300#s. Pretty sure they put those lifting eyes on there to pick and place the machine.

Last edited:

- Joined

- Nov 23, 2014

- Messages

- 2,606

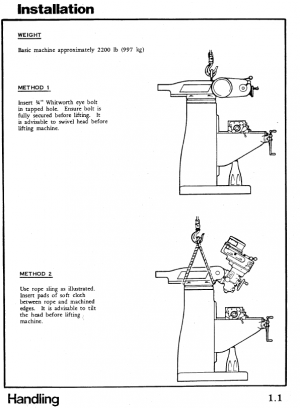

Correct on the eyebolt. The BP manual I downloaded from Vintage Machinery gives a couple of options. I'm guessing that they advised (in Method 1) to swivel the head before lifting for overhead clearance, not for balance.I unloaded my 9x49 Jet VS mill from a semi-tailer and into my shop with a 5,000# rated forklift, nylon strap through the lifting eye on the ram. Moved the ram for good balance point. About 2300#s. Pretty sure they put those lifting eyes on the to pick and place the machine.

Personally, I'd go with the lifting eye as long as you have one vetted for the machine (not a grade 5 hardware store eyebolt). Less variation in your lift than slings that could slip under tension. But I'm not a rigger, if it's in the manual showing both methods, either would work.

Bruce

- Joined

- Oct 11, 2016

- Messages

- 3,855

In contrast in the last half dozen moves of BP style mills I have not used the eye bolt. You can break the cross, but you can also break out the eye bolt section. I don't even lift from the ram. I lift from the bottom, and incorporate secondary straps to prevent tipping. I always lift from the strongest point on a machine, and then correct for centre of gravity.

- Joined

- Aug 13, 2020

- Messages

- 1,342

I certainly appreciate all the input. It's a big investment for me, and I'm not taking it lightly. I need the additional capability.

Haha!! I saw what you did there.

The Eye bolt lift has some advantages: the load can be easily rotated to get past obstacles and to set it down in the proper orientation. No risk of load shifting like on forks, especially risky if the surface the lift is traveling over isn't level. If you use a forklift make sure the load or slings can't slide on the forks! The factory has figured out the balance point for you, the factory has also figured out the stresses on components including safety factors. no need to figure out how to get the machine up onto the forks. No use reinventing the wheel! Nylon slings are pretty expensive but you can also rent them from the places that rent forklifts, & machinery skates. Heavy lathes commonly have two holes in the base to pass bars through to they can be lifted with slings. Some of the same advantages as using the lifting eyes on mills.

Above all, think it through before you start. A rigger may be the cheapest way in the long run.

Above all, think it through before you start. A rigger may be the cheapest way in the long run.

- Joined

- Oct 11, 2016

- Messages

- 3,855

I simply lift mills the same way, with slings, from the bottom, and stabilizing stings to the eye or to the ram. I never put the full load on the turret or above.Heavy lathes commonly have two holes in the base to pass bars through to they can be lifted with slings. Some of the same advantages as using the lifting eyes on mills.

People should never, ever lift steel/iron contacting steel (as in forks or machine skates). There must ALWAYS be a resilient layer between. Wood, rubber matting, or any high friction surface. "steel on steel is no deal"No risk of load shifting like on forks, especially risky if the surface the lift is traveling over isn't level.

- Joined

- Jul 13, 2017

- Messages

- 634

Another vote here for the drop bed trailer.

You can rig a come-along or even a chainfall to help finesse it on and off the trailer bed.

You can rig a come-along or even a chainfall to help finesse it on and off the trailer bed.

- Joined

- Aug 13, 2020

- Messages

- 1,342

Another tip: If dragging it with a come-along, arrange to drag it so that any slight tipping will be towards the back. these mills are face heavy. The uHaul I had was low, but it wasn't a drop bed. Still, it slid off the back and down the gate/ramp backwards with no issue. It was trying to get it in to the garage that tilted it towards the face that caused the crash.