- Joined

- Jul 10, 2013

- Messages

- 1,189

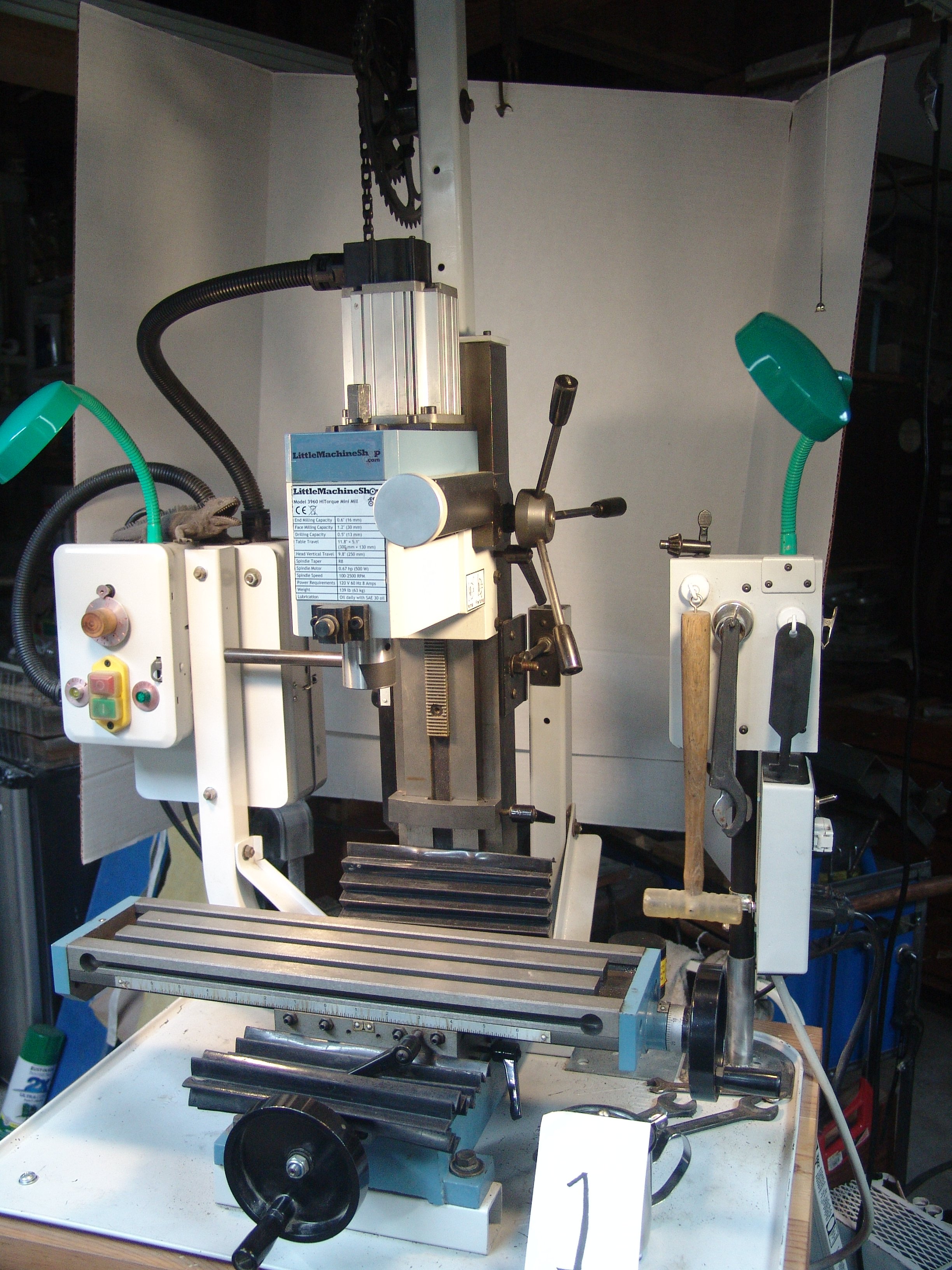

This is a series of mods for a LMS3960, but I think will work for other mills. It took me over two years to figure it out and make it work. One thing that made it difficult was that I wanted modify the main mill as little as possible. Except for drilling and tapping 10 holes, the mill can be put back to its original form. Sometimes, when I was half way through a mod, had to go back so that the mill can be used for some project even including a mod. Picture no.1 shows the completed mods on the mill.