As

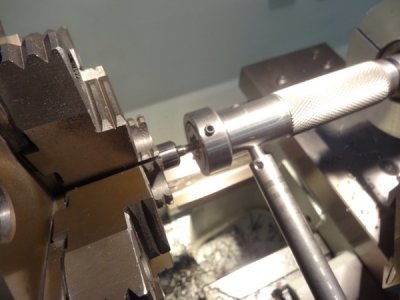

I just wrote in another thread, one milling tool I can't live without is a tramming tool / spindle square. I'd recommend it as a first project rather than buying a (quite expensive) commercial one.

I consider my spindle square every bit as essential as my milling vice (actually even more essential, now that I think about it). For the cost of a short piece of 1/2" drill rod, some 1" square aluminum bar stock, two socket head cap screws, and a couple cheapo harbor freight dial indicators you can build it pretty easily. See the following video from "Metal Tips and Tricks" on YouTube:

Now to get to the real task at hand: spending your money on tools. <laugh>

You got tee-slot nuts, but do you have a clamping kit or two (step blocks, etc.)? Low profile side clamps also come in handy. A rotary table is definitely a useful tool, but I'd wait until you have a project that needs one before you buy one. For a mill, you'll want an "indicol" style indicator holder. You ordered a DTI, but you'll probably want some (cheaper, fortunately!) dial indicators as well. You'll definitely want something with more travel than the 0.030" DTI (say a 1" indicator). You'll also want a mag base and holder (Noga is the brand you want, but there are cheaper knock-offs that aren't quite as nice).

FWIW, this isn't specific to milling, but my apron

always has the following in various pockets: A Starrett 6" combination square, a 6" flexible rule, a good 6" 5R rule, a magnetic pickup tool, an extendable mirror with light, a retractable scriber, an

old-school brass folding rule, a hunk of paraffin for lubricating screws or whatever, and three markers: a mechanical pencil, a sharpie, and a Dykem BriteMark paint stick. All of these see constant use.

Doubtless I could get by with a cheaper combination square, but I use the sucker constantly and it's a joy to use. The extendable pickup tool and mirror also see constant use.

The folding rule and paraffin are leftovers from my woodworking days, but I still use them regularly even with metalworking. I rarely need to measure anything more than 12" for metalworking, and when I do I don't need more than 1/8" precision. The folding rule is far, far handier to me than a tape measure for anything longer than a 12" rule that will still fit on my milling table.

The sharpie is mostly for notes to myself that I write on the vise or on the milling table directly. I don't use it much for marking parts because it wipes off so easily (any oil or solvent will usually cause it to come off). I'm a huge fan of the Dykem Brite-Mark paint sticks for marking parts, though. Those marks don't come off until I want them to.

The tools you carry on your person are the most interesting to me. Seems like that would be far more interesting than all the "what's in your toolbox" videos on YouTube. "What's in your pockets?" <laugh>

Regards,

--

Rex