You may of read in another thread about my search for a lathe, well search is over. I bought a Rockwell 11" , model 25-100 lathe the other day and brought it home last week.Included is a 3 & 4 jaw chuck, quick release tool post with various tool holders, steady rest, turret attachment, live and dead centers, Jacobs chuck, hand full of bits, older style tool holders and an assortment of wrenches. A collet closer is also in the mix. The motor is a three phase and I've ordered a Teco converter wih VFD.

The seller says it sat for the past ten years, and I'd have to say the condition supports that. Everything seems to move and engage fine. Needs a good cleaning and lube job. I can't wait to get the converter so I can fire up and really check it out.

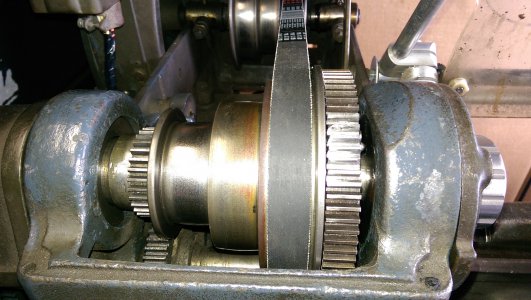

The one mistake I made I didn't take the headstock cover off. I rotated the spindle by hand and everything sounded fine. When I removed the cover, I discovered the bull gear and the bevel gear to the left of it are missing teeth. Guess I screwed up by not finding this before I bought. Well, it's sitting in my shop now and I'll jus have to move forward with it.

Ive been posting over on the Yahoo group and received some good feed back. Some ideas are buying the repair gears from Plaza, welding and filling new teeth or see if I can buy a couple of gears.

I believe all else is ok, the shaft on the quick change box may need bushings/bearings. I've been told I can use as is, just won't have the reduction. My be what I do for a while. A welder at work said he could weld it and we could dremel and file new teeth, I may go that route, don't have much to loose.

Love to hear your comments and any help would be appreciated .

Craig

The seller says it sat for the past ten years, and I'd have to say the condition supports that. Everything seems to move and engage fine. Needs a good cleaning and lube job. I can't wait to get the converter so I can fire up and really check it out.

The one mistake I made I didn't take the headstock cover off. I rotated the spindle by hand and everything sounded fine. When I removed the cover, I discovered the bull gear and the bevel gear to the left of it are missing teeth. Guess I screwed up by not finding this before I bought. Well, it's sitting in my shop now and I'll jus have to move forward with it.

Ive been posting over on the Yahoo group and received some good feed back. Some ideas are buying the repair gears from Plaza, welding and filling new teeth or see if I can buy a couple of gears.

I believe all else is ok, the shaft on the quick change box may need bushings/bearings. I've been told I can use as is, just won't have the reduction. My be what I do for a while. A welder at work said he could weld it and we could dremel and file new teeth, I may go that route, don't have much to loose.

Love to hear your comments and any help would be appreciated .

Craig