I picked up a 1ton arbor press a few weeks ago. I needed to punch some holes in spring steel, I was using a hand punch and well My hands were getting tired

So I went to HF and picked this thing up on sale.

First order of buisness was to get a hole in here..

This was somewhat of a dilema I have a very small drill press(on my list of things that needs upgraded) and I had just purchased a 7x10 lathe. I figured no way I could fit the quill in either of those to make a nice center hole.. I made some calls had the use of a large lathe lined up it fell threw and here is plan B.

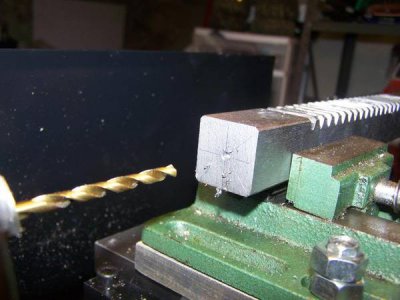

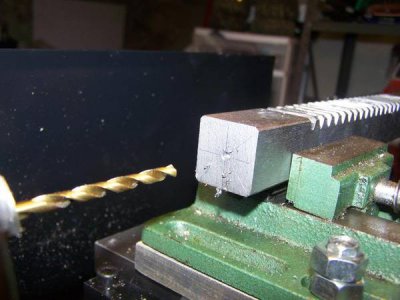

I cut a quick plate out and mounted it on the lathe where the compound was at.

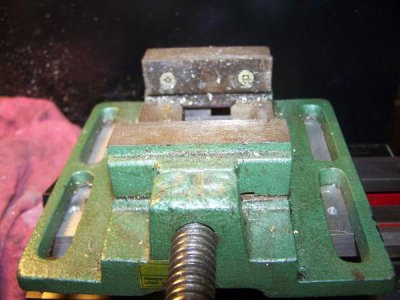

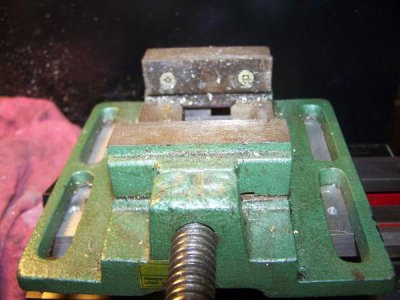

I then got the old cheapy drill press vice off the welding bench.

I centered it all up and drilled away..

and fit was pretty good..

While i had it all tore down I also made this little mod. removed the bottom couple teeth with the old angle grinder to make the press ratchet..

I got the idea for the ratchet from a youtube video.. pretty good idea..

[video=youtube;tFfx2_bj104] http://www.youtube.com/watch?v=tFfx2_bj104 [/video]

well all in all I am pretty happy with now owning this little tool its came in handy several times now..

View attachment Picture129.jpg

So I went to HF and picked this thing up on sale.

First order of buisness was to get a hole in here..

This was somewhat of a dilema I have a very small drill press(on my list of things that needs upgraded) and I had just purchased a 7x10 lathe. I figured no way I could fit the quill in either of those to make a nice center hole.. I made some calls had the use of a large lathe lined up it fell threw and here is plan B.

I cut a quick plate out and mounted it on the lathe where the compound was at.

I then got the old cheapy drill press vice off the welding bench.

I centered it all up and drilled away..

and fit was pretty good..

While i had it all tore down I also made this little mod. removed the bottom couple teeth with the old angle grinder to make the press ratchet..

I got the idea for the ratchet from a youtube video.. pretty good idea..

[video=youtube;tFfx2_bj104] http://www.youtube.com/watch?v=tFfx2_bj104 [/video]

well all in all I am pretty happy with now owning this little tool its came in handy several times now..

View attachment Picture129.jpg

Last edited by a moderator: