- Joined

- Oct 4, 2016

- Messages

- 7,012

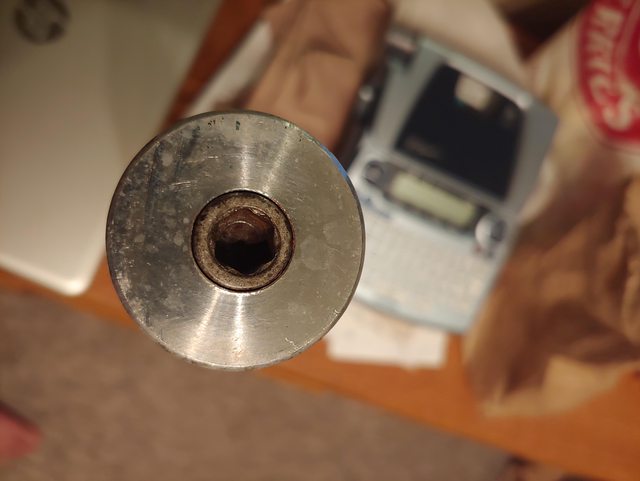

2" x 24" 6061 to start, I only got a little bit done tonight. I love aluminum, no drama. I even hit an all time high RPM for me 1200( could go more, working on courage still). My only hate on it is it won't clean up with a magnet, aluminum fecal matter is all over the place, the blank was 7 lbs to start. It's a prototype, so we'll see  I'm thinking a Billy club type design, with knurling, and a decent taper....

I'm thinking a Billy club type design, with knurling, and a decent taper....

I'm thinking a Billy club type design, with knurling, and a decent taper....

I'm thinking a Billy club type design, with knurling, and a decent taper....