- Joined

- Mar 2, 2018

- Messages

- 232

My username is also the name of the shop equipment condensation management system I spent a couple of weeks putting together. It's finally alive, and it's working!

I could afford equipment or building, but not both, and it's hard to make stuff with a building. I have an unheated, uninsulated shop with a dirt floor, and I've been battling serious condensation problems all winter. I ran across a guy on Youtube who had put together an Arduino-based system to manage this problem, but he wasn't very forthcoming with the details. He provided the operating theory, but I had to go off and learn enough to put a system together and make it happen for myself. This was rewarding, but it was not fun.

I spent a couple weeks of spare time working on this thing. I get temperature and relative humidity from a sensor, and use that to calculate the dew point with some math I stole off the internet and could never explain. I have a temperature sensor mounted on my mill and my lathe, and each machine has a pair of silicone pad heaters plugged into a relay for that machine. The system logic turns on the heat as required to warm the equipment to 1°C above the dew point. I bench tested it thoroughly, and after all these hours of banging my head against the wall chasing bugs in both the hardware and the software, I finally deployed the system in my shop yesterday.

It's cold outside and very foggy, so I rushed out to the shop as soon as I got home to see how the system was working. I was greeted with this display:

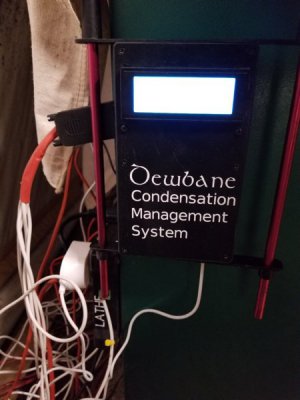

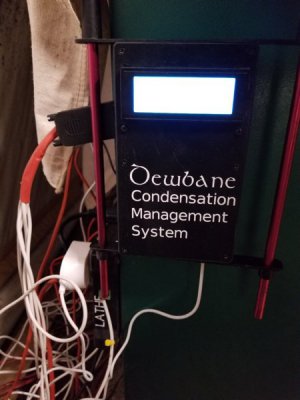

Here's what the box looks like (doubling as a handy hanger for my parallel keeper), along with the lathe relay box:

I will tidy up the wiring tangle after I establish that my sensor placement is going to work. I drilled a hole in the lathe bed casting at the headstock end (g0602), just above the tunnel. If I ever run into a combination of change gears that interferes with that, I'll have to back up and punt. On the mill (g0704), I mounted the sensor in the plastic box that used to house the worthless chip shield that was constantly in my way. On the lathe, I mounted one heater toward the far end where the tailstock is usually parked, and I mounted the other just below the ways, as close to the headstock as possible. On the mill, I ended up mounting both of the heaters on the back of the column, because nothing else seemed workable.

Time till tell how the system performs, but so far, so good! Dew point 34°F, very high relative humidity, but my equipment is at 35 and 36, and it's bone dry. I don't yet have any idea how fast the equipment will heat up, what temperatures it can reach, or if this system has enough potential to keep my equipment condensation free under all circumstances. It's off to a good start, and I was stoked to come home and find the system had done its job.

I could afford equipment or building, but not both, and it's hard to make stuff with a building. I have an unheated, uninsulated shop with a dirt floor, and I've been battling serious condensation problems all winter. I ran across a guy on Youtube who had put together an Arduino-based system to manage this problem, but he wasn't very forthcoming with the details. He provided the operating theory, but I had to go off and learn enough to put a system together and make it happen for myself. This was rewarding, but it was not fun.

I spent a couple weeks of spare time working on this thing. I get temperature and relative humidity from a sensor, and use that to calculate the dew point with some math I stole off the internet and could never explain. I have a temperature sensor mounted on my mill and my lathe, and each machine has a pair of silicone pad heaters plugged into a relay for that machine. The system logic turns on the heat as required to warm the equipment to 1°C above the dew point. I bench tested it thoroughly, and after all these hours of banging my head against the wall chasing bugs in both the hardware and the software, I finally deployed the system in my shop yesterday.

It's cold outside and very foggy, so I rushed out to the shop as soon as I got home to see how the system was working. I was greeted with this display:

Here's what the box looks like (doubling as a handy hanger for my parallel keeper), along with the lathe relay box:

I will tidy up the wiring tangle after I establish that my sensor placement is going to work. I drilled a hole in the lathe bed casting at the headstock end (g0602), just above the tunnel. If I ever run into a combination of change gears that interferes with that, I'll have to back up and punt. On the mill (g0704), I mounted the sensor in the plastic box that used to house the worthless chip shield that was constantly in my way. On the lathe, I mounted one heater toward the far end where the tailstock is usually parked, and I mounted the other just below the ways, as close to the headstock as possible. On the mill, I ended up mounting both of the heaters on the back of the column, because nothing else seemed workable.

Time till tell how the system performs, but so far, so good! Dew point 34°F, very high relative humidity, but my equipment is at 35 and 36, and it's bone dry. I don't yet have any idea how fast the equipment will heat up, what temperatures it can reach, or if this system has enough potential to keep my equipment condensation free under all circumstances. It's off to a good start, and I was stoked to come home and find the system had done its job.