- Joined

- Nov 14, 2016

- Messages

- 2,995

Well no pictures today. Just some information in hopes of some suggestions.

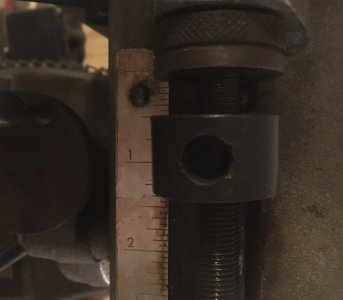

First, the quill won't fully extend. It stops a bit short. I feel like I could force it, but am hesitant to inadvertently scratch, scar, of break something. Any ideas?

Secondly, the missing power feed is fine. I know I'll never find a working original. But the PO stuck a handwheel on that side which I believe belongs on a little lathe. I'm torn between ignoring it, buying a servo power feed, and making some kind of cap, or painstakingly trying to make realistic replacements of dial and handwheel by copying the left side unit. What would you do?

Lastly for now, the motor leads are toast, and I believe the windings are open. It's a dual voltage single phase motor. Again, what would you do? Three phase and VFD? The motor shaft is over 4" long. Looks expensive. Lol

Good to find out why the quill won't extend but not that big of a deal in the short term as long as it isn't damaged. The only time I use the quill is drilling, the knee is much more accurate and solid when milling.