-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My first knee mill

- Thread starter jwmay

- Start date

- Joined

- Oct 7, 2020

- Messages

- 2,111

Looking good!

- Joined

- Oct 14, 2013

- Messages

- 982

here's the core holes in the back of the knee. If you ever are in a position to see them on -your- mill, plug them! They let chips get on your bevel gears!

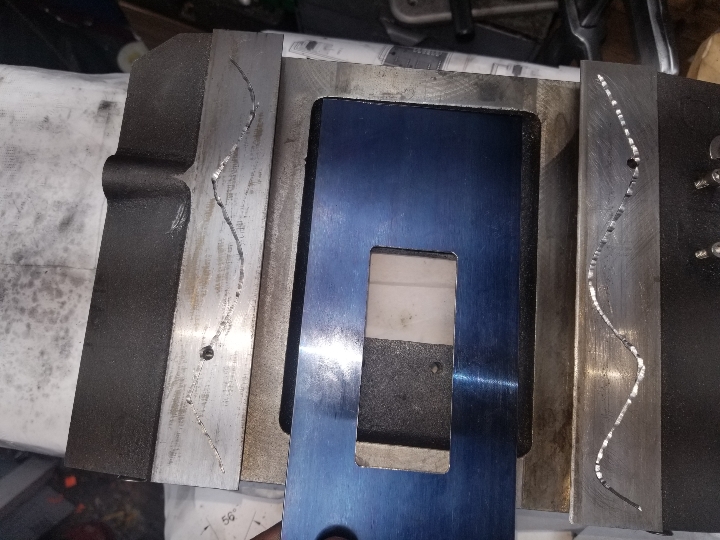

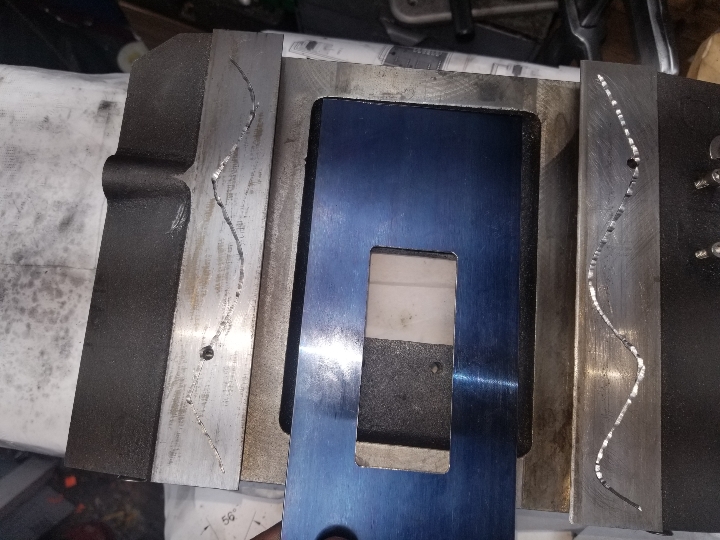

I'm knee deep adding/improving my Rockwell right now. Any interest I'm my posting the progress? You can see the new lube grooves and ports...

Sent from my SM-G892A using Tapatalk

I'm knee deep adding/improving my Rockwell right now. Any interest I'm my posting the progress? You can see the new lube grooves and ports...

Sent from my SM-G892A using Tapatalk

- Joined

- Dec 3, 2017

- Messages

- 1,909

Any interest I'm my posting the progress?

Yeah of course! You're doing the hard stuff! I'd love to read all about it. Thanks for showing the core holes. I didn't realize there were two.

I'm just scrubbing mine clean as best I can so I can use it. I wish I had the skill and patience to do what you're doing. Probably not in the cards for me though. I need to get alot better at machining first. At this rate, I'll be out of time before I get that skill mastered. Lol

- Joined

- Dec 3, 2017

- Messages

- 1,909

- Joined

- Dec 3, 2017

- Messages

- 1,909

There was about 8 Solo cups worth of chips up inside the knee. I don't want to remove it, so I fashioned a fancy bent hook, sat on my knees with a flashlight and dug "most" of it out. Here's a picture looking up in the knee casting, a picture of where the bevel gears are, and a couple pics of a contraption to separate the knee dial and crank from the carrier. All three pieces were seized together. It really seems like maybe this had cosmoline on it, and it was never cleaned off. It's obviously been used plenty.

As for the bevel gears, I stuck my flexi spout oiler up in there and gave it a half dozen pumps. Hopefully that'll wash out any big chips left over. I've got half a mind to drag a small coolant pump over and run a nozzle up in the casting and wash down all that stuff properly. But I doubt the other half of my mind will ever be that motivated. The mill lasted this long with no lube, maintenance or cleaning. It'll probably outlast me so long as I'm the one at the helm.

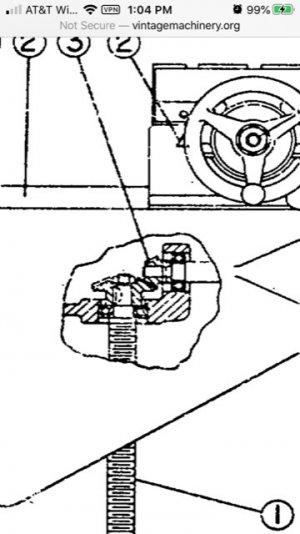

Credit where it's due, my digital images of the manual came from vintagemachinery.org. It's also in the downloads section of this forum.

As for the bevel gears, I stuck my flexi spout oiler up in there and gave it a half dozen pumps. Hopefully that'll wash out any big chips left over. I've got half a mind to drag a small coolant pump over and run a nozzle up in the casting and wash down all that stuff properly. But I doubt the other half of my mind will ever be that motivated. The mill lasted this long with no lube, maintenance or cleaning. It'll probably outlast me so long as I'm the one at the helm.

Credit where it's due, my digital images of the manual came from vintagemachinery.org. It's also in the downloads section of this forum.

Attachments

- Joined

- Oct 14, 2013

- Messages

- 982

I found out why my sliding swarf guard got bent!!! I screwed up :-(

If you put them on backwards, they can -just- slide far enough so that the top guard gets hooked on the bottom of the saddle casting!

The photo is the correct direction!

Sent from my SM-G892A using Tapatalk

If you put them on backwards, they can -just- slide far enough so that the top guard gets hooked on the bottom of the saddle casting!

The photo is the correct direction!

Sent from my SM-G892A using Tapatalk

- Joined

- Dec 3, 2017

- Messages

- 1,909

Since you brought that up, the manual states that you can expose the bevel gears for lubrication by sliding those covers. I've slid them every way I could think, and there's never an opening. Since yours is completely apart, do you see any way that can happen?

- Joined

- Oct 14, 2013

- Messages

- 982

That means you have them on backwards :-(

I'll take a picture tomorrow.

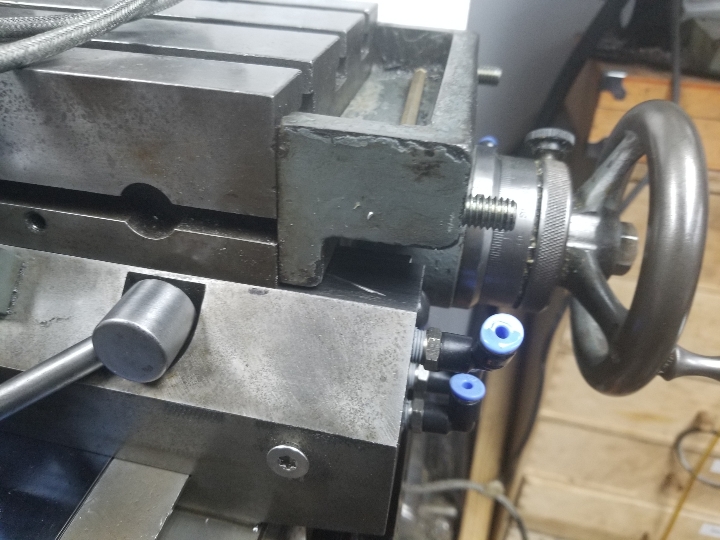

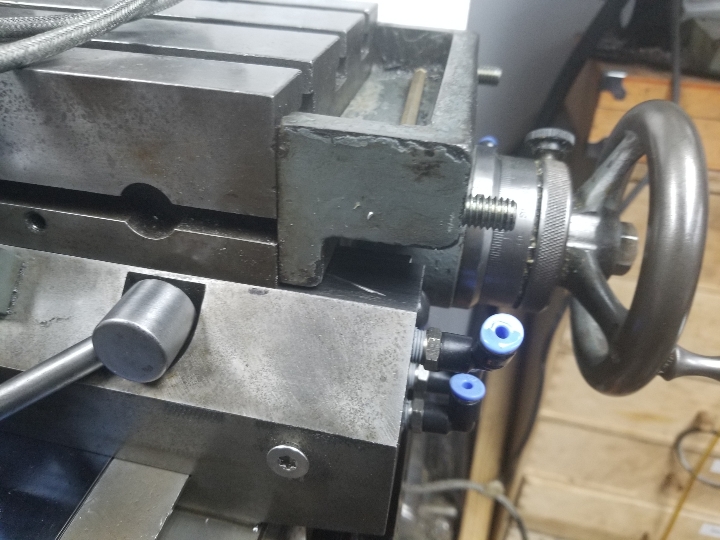

Here's where you want to put the hand wheel to tighten the mounting bolts.

Sent from my SM-G892A using Tapatalk

I'll take a picture tomorrow.

Here's where you want to put the hand wheel to tighten the mounting bolts.

Sent from my SM-G892A using Tapatalk