- Joined

- Aug 6, 2015

- Messages

- 3,871

Starting a thread in the correct section after buying my first lathe!! Thank you all for your feedback on the initial thread in the General Section.

Purchased on September 14, 2021

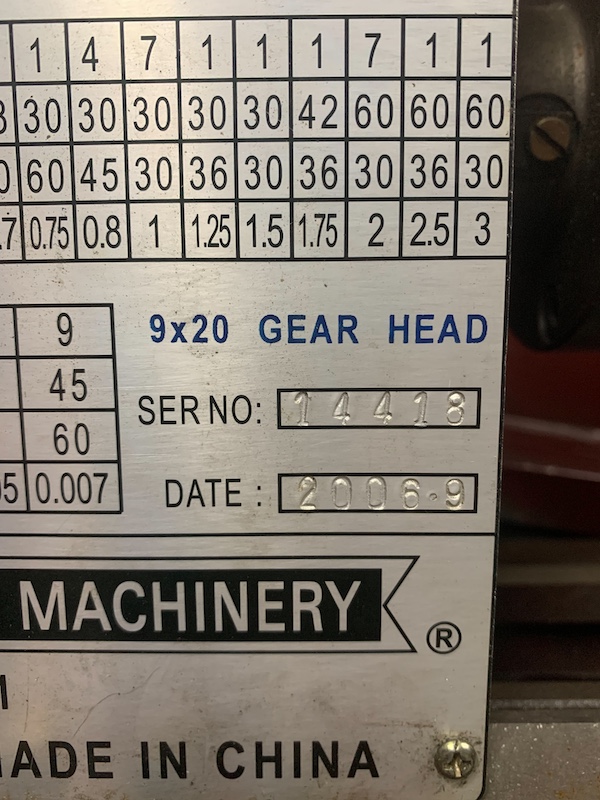

It is a Central Machinery (Harbor Freight) 9" x 20" geared head belt driven, bench lathe. Built in September, 2006.

Paid 500.00 for it with what you see in the photos (Craftsman bench included as well).

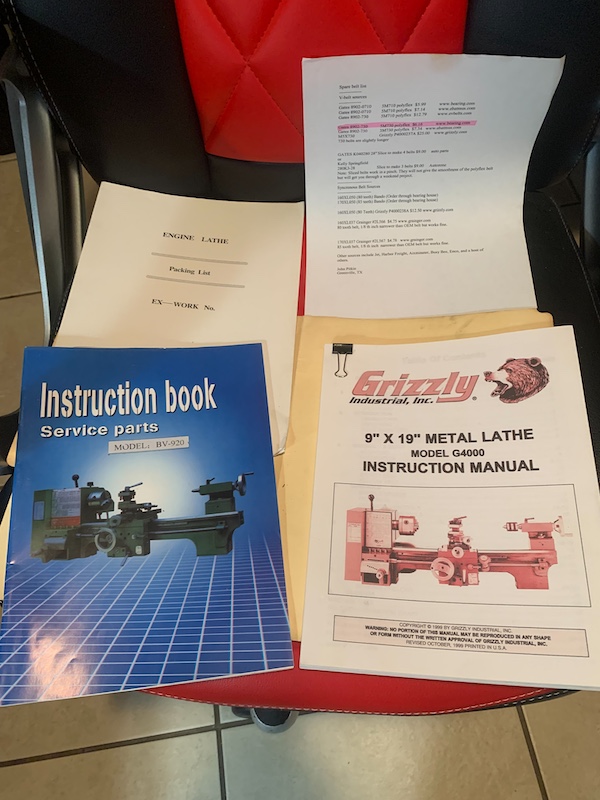

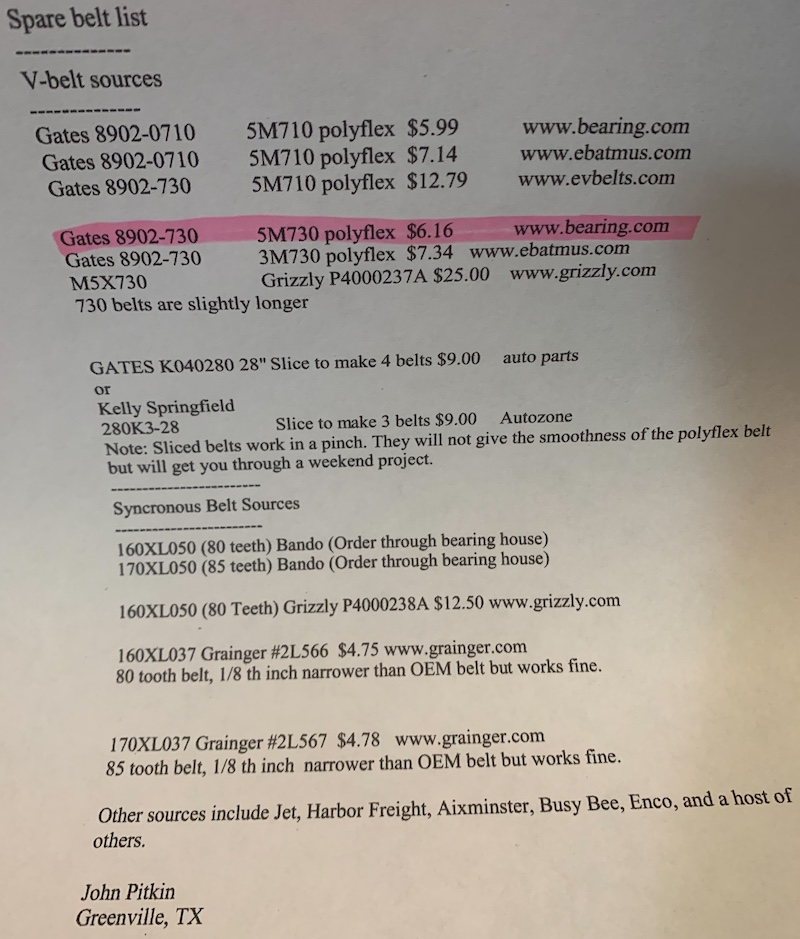

Manuals and original purchase receipt included... There was also a printed manual for the Grizzly G4000 (better documentation).

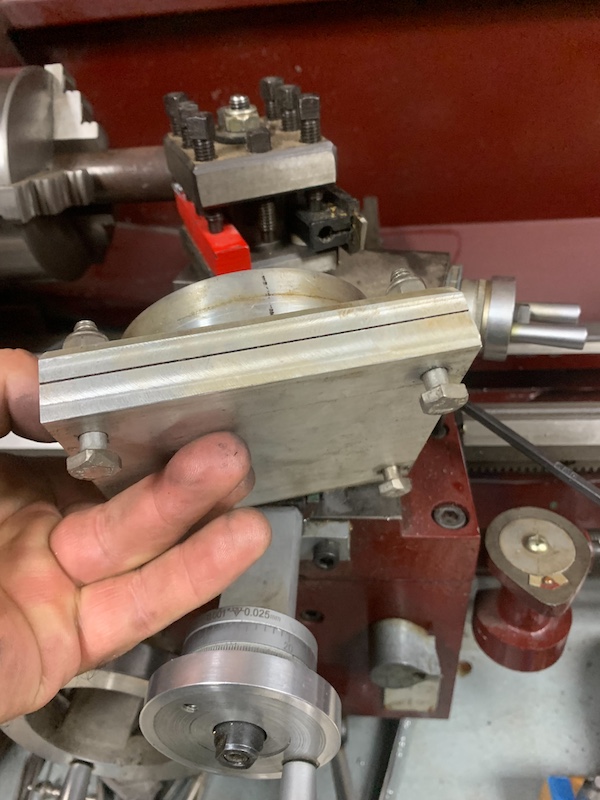

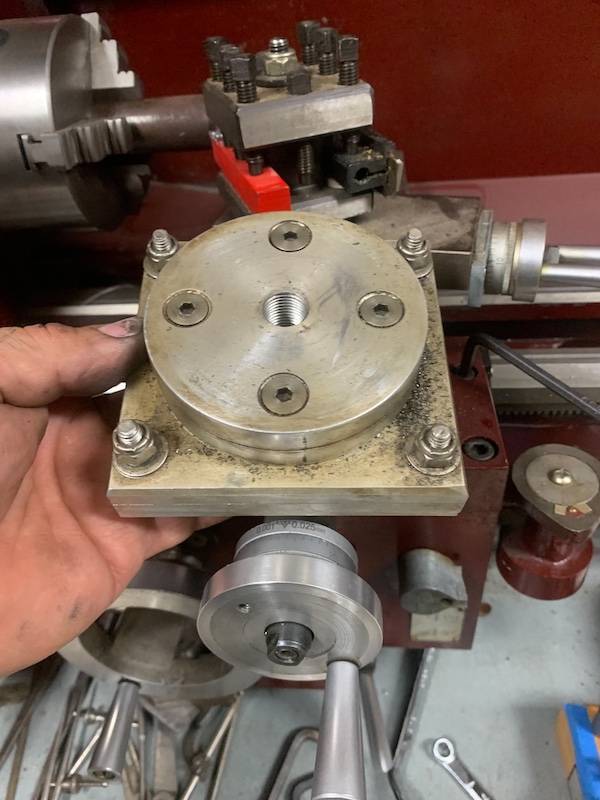

And this, that I am searching to see what it is for...

Everything looks to be in working order and in good condition. I did clean it, took apart the compound, checked the gibs, and cleaned and oiled everything.

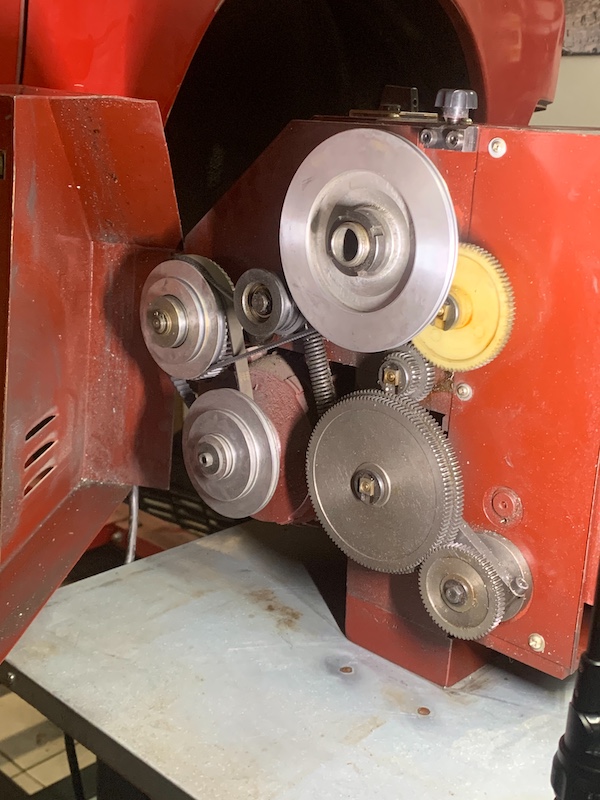

Photo looking at the gears for the feed rate...

And a recent photo...

Purchased on September 14, 2021

It is a Central Machinery (Harbor Freight) 9" x 20" geared head belt driven, bench lathe. Built in September, 2006.

Paid 500.00 for it with what you see in the photos (Craftsman bench included as well).

Manuals and original purchase receipt included... There was also a printed manual for the Grizzly G4000 (better documentation).

And this, that I am searching to see what it is for...

Everything looks to be in working order and in good condition. I did clean it, took apart the compound, checked the gibs, and cleaned and oiled everything.

Photo looking at the gears for the feed rate...

And a recent photo...

Attachments

Last edited:

That plate "might" be for mounting a Ball Turning device on it, less the post and the tool itself....best guess

That plate "might" be for mounting a Ball Turning device on it, less the post and the tool itself....best guess