Now that my mill is all set up, I found my first real use for it. To tighten or loosen the collet drawbar you are supposed to open the top cover and hold the pulley with your hand, but that doesn't seem ideal. I have seen the commercially available spindle wrench but in my case, at least, the spindle splines don't protrude above the closed cover so I needed a wrench with more of a socket style that could go down in the hole in the cover to reach the splines. This is how I did it:

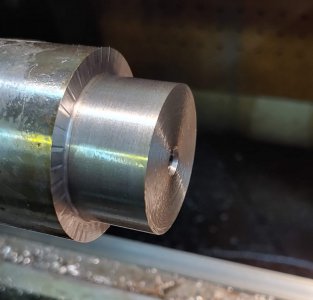

First, I roughed out a blank (1.5" OD) on the lathe for the "socket" and drilled a 1/4" hole through it. I cut it off with my horizontal band saw rather than bothering to part it off since I had to finish the back side of it anyway.

I mounted the blank in the vise with V blocks and parallels below it. I carefully chose the height of the head so that I would be able to fit the coaxial indicator in the drill chuck and also have enough quill travel to reach the part with a center drill. Thinking about it later, I could have mounted the indicator in a collet instead of the drill chuck and saved a lot of distance.

After centering the part, I zeroed the readings on the DRO (not actually necessary once physically centered) and then entered the bolt circle program.

I don't know how hard it is to use a bolt circle function on a strictly numeric DRO but I really like the graphic display on this one. You can see where you are easily and follow the steps in order or move to any hole you want in any order. For instance, you could drill all six holes with only setting the Y position 3 times by going left-right-up-down instead of in a circle for more economy of motion. I started all six holes with a center drill and then stepped through them again with a 9/32" bit that I chose to fit over the male splines.

Next, I changed the spindle speed to my lowest setting and drilled out the center with a 7/8" bit.

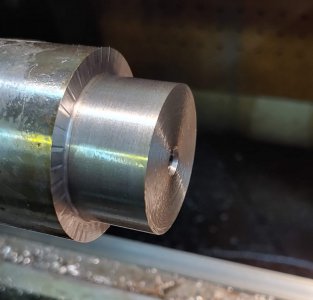

Next, I put the part back in the lathe. I bored the center out to a little over 23mm for an easy fit over the base diameter of the splines and then faced and chamfered both faces, inside and out. When I checked the fit on the splines, I was very happy with it.

Finally, I made a handle and welded it on and painted the wrench. It fulfilled my vision for it which is always very satisfying.

Now my mill is all dressed up and nowhere to go! I don't know what to make next.

Rob

First, I roughed out a blank (1.5" OD) on the lathe for the "socket" and drilled a 1/4" hole through it. I cut it off with my horizontal band saw rather than bothering to part it off since I had to finish the back side of it anyway.

I mounted the blank in the vise with V blocks and parallels below it. I carefully chose the height of the head so that I would be able to fit the coaxial indicator in the drill chuck and also have enough quill travel to reach the part with a center drill. Thinking about it later, I could have mounted the indicator in a collet instead of the drill chuck and saved a lot of distance.

After centering the part, I zeroed the readings on the DRO (not actually necessary once physically centered) and then entered the bolt circle program.

I don't know how hard it is to use a bolt circle function on a strictly numeric DRO but I really like the graphic display on this one. You can see where you are easily and follow the steps in order or move to any hole you want in any order. For instance, you could drill all six holes with only setting the Y position 3 times by going left-right-up-down instead of in a circle for more economy of motion. I started all six holes with a center drill and then stepped through them again with a 9/32" bit that I chose to fit over the male splines.

Next, I changed the spindle speed to my lowest setting and drilled out the center with a 7/8" bit.

Next, I put the part back in the lathe. I bored the center out to a little over 23mm for an easy fit over the base diameter of the splines and then faced and chamfered both faces, inside and out. When I checked the fit on the splines, I was very happy with it.

Finally, I made a handle and welded it on and painted the wrench. It fulfilled my vision for it which is always very satisfying.

Now my mill is all dressed up and nowhere to go! I don't know what to make next.

Rob

Last edited: