The shame, the shame, the shame... but I will share it anyway... So I secure this stock in the vise... I get the largest cutter I have, 3/4" 4-flute end mill... I am saying in my mind... I have a Wells-Index... this puppy is going to eat this like there is no mañana... So I go for a single cut of all the material that needs to be removed... And to top it off, I start cutting in the wrong direction... yeah, climb milling instead of conventional... So the end mill digs into the side of the part and the machine stops... I hit the E-Stop.... and I am just going "you stupid F****!!!" You had to try to do this in one pass instead of several cuts, and on top of that, you forget the proper direction to cut it from" Arrggggghhhh....

But wait... it gets better... You would think that I would have checked to see if the vise moved with all this... But nooooooo... Instead I removed the 4-flute end mill, well, because in the process I broke one of the flutes... Install a new one and continue the work...

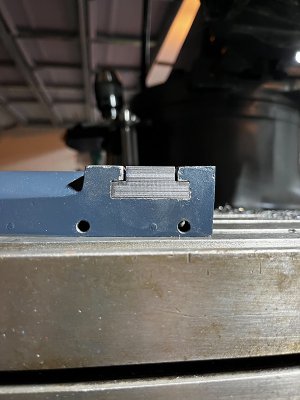

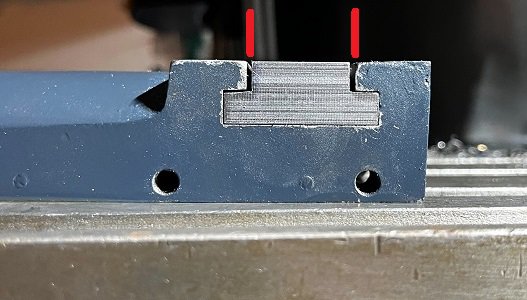

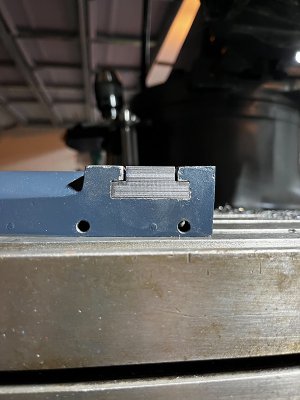

A complete mess... I figure all this is wrong when I remove the part and test fit it to the compound... goodness...

So I swallow my pride, after finding it, and proceed to fix the vise....

Then to square the cuts on the top...

And mill the length to correct dimension..

Now, I do not have any more material here... all that is back in Orlando... so I just continue to try to at least square the cuts made... All goes well from this point on but the top of the T-Nut ends up smaller than in needs to be... duh!

So now I am thinking... do I leave it as is? Do I redo the part? Not sure what to do... It was going so well until I got greedy trying to remove material... what a dumba***....