-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Logan 820 Lathe Journey

- Thread starter wachuko

- Start date

- Joined

- Feb 13, 2017

- Messages

- 2,138

That machine looks too pretty to use. It should be in a museum somewhere.

- Joined

- Aug 6, 2015

- Messages

- 3,862

Nice!!!

one more post with side by side before and after pics?

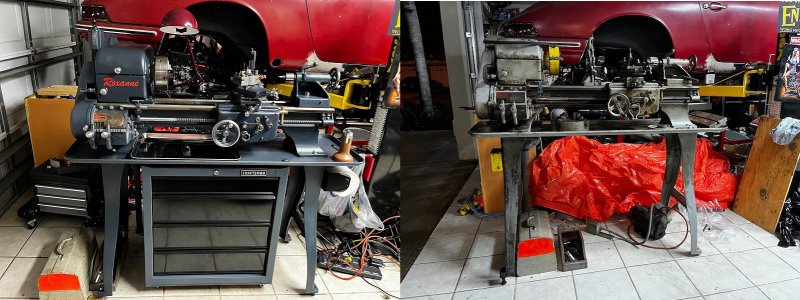

Like this?

The part that I am so grateful for is that everything was working fine and tight... All that I did was mostly cosmetic... Cleaning and paint...

Oh, and I ended moving the switch to its stock location...

Only things replaced or added:

New Ways Felts

New Half Nuts

Purchased missing Follow Rest and Clutch Knob

PWT Tool Post

New Live Center

New 3C Collect Setup

New ER32 Setup

Added a Vintage Lamp

Removed all outlet boxes installed by prior owners. Pretty sure I will be adding one of those back...

That machine looks too pretty to use. It should be in a museum somewhere.

I will add a Museum sign to my garage... How is that? hahahahahaha... It will get used. I want this one to be my primary lathe and just use the G0709 for anything this cannot tackle... There is a great and unmeasurable feeling that I get from using vintage tools... I really like it.

- Joined

- Jul 6, 2022

- Messages

- 498

Like this?

View attachment 418145

The part that I am so grateful for is that everything was working fine and tight... All that I did was mostly cosmetic... Cleaning and paint...

View attachment 418146

Oh, and I ended moving the switch to its stock location...

View attachment 418147

View attachment 418148

View attachment 418149

Only things replaced or added:

New Ways Felts

New Half Nuts

Purchased missing Follow Rest and Clutch Knob

PWT Tool Post

New Live Center

New 3C Collect Setup

New ER32 Setup

Added a Vintage Lamp

Removed all outlet boxes installed by prior owners. Pretty sure I will be adding one of those back...

I will add a Museum sign to my garage... How is that? hahahahahaha... It will get used. I want this one to be my primary lathe and just use the G0709 for anything this cannot tackle... There is a great and unmeasurable feeling that I get from using vintage tools... I really like it.

Amazing transformation. Well done. I’m looking forward to seeing some posts of it in action!

Are you planning on a DRO?

Sent from my iPhone using Tapatalk

- Joined

- Aug 6, 2015

- Messages

- 3,862

Amazing transformation. Well done. I’m looking forward to seeing some posts of it in action!

Are you planning on a DRO?

Thank you for the kind words. I will be installing a DRO on the G0709 first... not sure if I will do the same with this one...

Still no action photos... I thought I was done but found out that the previous owners, seeing the zerk fittings, used grease instead of way oil...

Since I wanted to replace the half-nut, everything needed to come out again. So took out the zerk fittings, cleaned all the grease. Replaced the half-nut... installed new zerk fittings.

Half-nut assembly out...

Comparing new versus the ones I am replacing...

New ones installed and ready to drop in place...

Pins were in excellent shape.

Now installed in place...

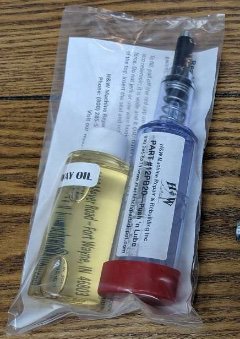

Ordered this to push way oil in there... Push N Lube Pump for Zerk - for now I just oiled the ways and inserted oil in the holes before installing the fittings.

New zerk fittings in place...

- Joined

- Oct 31, 2015

- Messages

- 463

In my experience, the flat belt from the countershaft to the spindle slips before the V-belt does.Logan lathes came with a flat pulley on top and a v on the bottom.

I have heard that placing a piece of old style black electrical tape completely around the flat belt pulley makes it less likely to slip. Gives it more traction?

- Joined

- Aug 6, 2015

- Messages

- 3,862

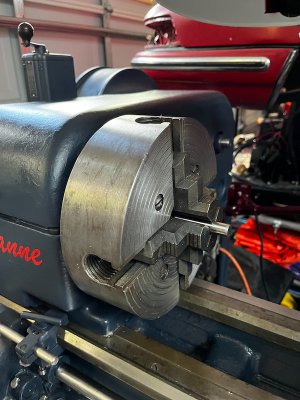

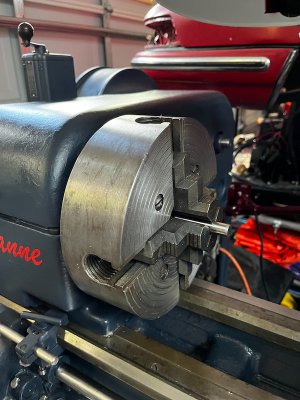

Finishing a few small tasks... but I think that I will be needing a four-jaws chuck...

Painted, to match, the back of the faceplate... it had been painted gray...

I took apart the 4-jaws chuck. Cleaned it... removed the paint applied by previous owners... and painted the back to match.

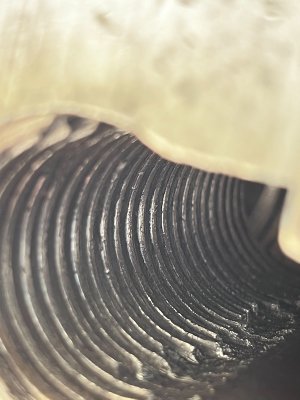

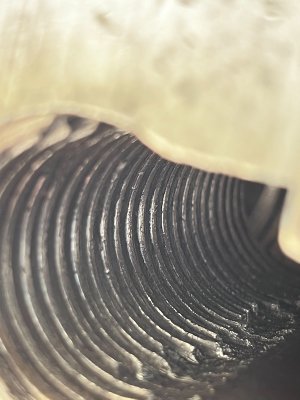

When I started to assemble I noticed this:

The threads for the jaws bolts are in bad shape...

Painted, to match, the back of the faceplate... it had been painted gray...

I took apart the 4-jaws chuck. Cleaned it... removed the paint applied by previous owners... and painted the back to match.

When I started to assemble I noticed this:

The threads for the jaws bolts are in bad shape...

- Joined

- Jan 25, 2015

- Messages

- 2,558

Kinda looks like:Some of the tools that came with the lathe... need to clean them up...

View attachment 418400

This one I have no idea what it is for????

View attachment 418397

View attachment 418398

View attachment 418399

I also seem to recall reading somewhere female centers were used for holding things that have a point or things that can’t have a centering hole drilled in them (like a motor armature, etc).

Last edited:

- Joined

- Aug 6, 2015

- Messages

- 3,862

Thank you. Looks like I found something I did not know that I needed. The one in the link is more than I want to spend, but I see less expensive alternatives. Cool!Kinda looks like:

I also seem to recall reading somewhere female centers were used for holding things that have a point or things that can’t have a centering hole drilled in them (like a motor armature, etc).