-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Logan 820 Lathe Journey

- Thread starter wachuko

- Start date

- Joined

- Aug 6, 2015

- Messages

- 3,873

Also called cup center. Can be handy .

I will get one of those inexpensive kits that have interchangeable tips. I wanted something that I could use on pipes/tubing... so seeing that there is a set that covers different applications, I will go with that.

And to consolidate the stuff I have been getting for the lathe...

Got a few solid carbide small boring bars... just to practice... found those on eBay.

15amp multiple outlet. Same one I have on the HF9x20. I will fix this one to the side of the toolbox.

Was able to find new old stock (NOS) chucks... US$190.00 each... came out to US$505.00 for both with shipping and taxes included. Got them from HH Roberts out of Canada. Wanted chucks with integrated/integral threaded setups in the hopes that these do not protrude more than the stock units...

New (NOS) 5” 3-jaw Bison 2-piece jaw chuck with integral threaded 1-1/2”x8 tpi mount

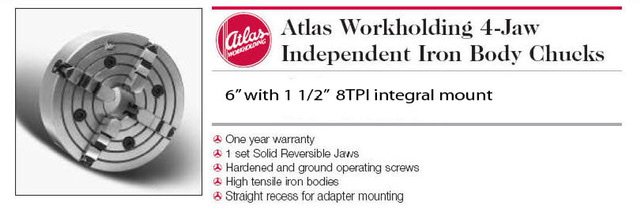

New (NOS) 6” 4-jaw Atlas chuck with integral threaded 1-1/2”x8 tpi mount - stock one that I have is 8"... but 6" will do just fine. If I need to work something larger I can always take it over to the Grizzly lathe...

Used Buck 5" 6-jaw chuck. Well, two in fact... I just need to make a backplate for one of them. Thanks to @mattthemuppet2

ER32 collet set - 1/16"-3/4"

Cheap Türlen Test Dial Indicator 7 Jewels High Precision 0.0005" - I break these so often that is not even funny... this is my 3rd or 4th... I have a better one that I am always afraid to take out of its case...

30X Jewelers Loupe

Pending stuff:

- DRO - I have some iGaging iP54 Electronic Digital Scales that I never used for the G0704... and since I went CNC with that one, I will not need them. Also, I still have the TouchDRO box I made... and the tablet is around here somewhere... Will see if I can repurpose those and do something similar to what Matt did ( Link to his setup ).

- Redo the wooden wheel for the ER32 collet drawbar. The one I made was just to practice. Now I want to make it out of some better wood...

- Need chuck keys for the Jacobs drill chucks... those were missing. But I am not close to the lathe. Will order those when I am in Orlando and can measure the size.

- Need to make the gib for that extra cross slide

- MT2 tapered drill chuck. Just want a new one for when the lathe is done. But pretty sure that I will better off restoring the Jacobs chuck that came with the lathe

- < this one left blank on purpose for future entry >

Last edited:

- Joined

- Aug 6, 2015

- Messages

- 3,873

Sweet!Now all you need is an inside collet. For holding on the bores of parts.

Rex Walters made a nice one for his 10 inch Logan check it out.

Search this site.

Grabbing on the inside

My friend @jimsehr showed me something a while back that rocked my world. Jim's got a few years on me, and I've learned to pay attention when old-timers take the time to show you something. How many parts have you made that looked something like this: Now, how many parts have you made that...

www.hobby-machinist.com

www.hobby-machinist.com

- Joined

- Aug 6, 2015

- Messages

- 3,873

Placing this here for future reference when I tackle the DRO install... Simple install. I like it... and able to use what I have. Only deviation from what he did is that I will try to keep the original cover on the cross slide... will see if that is possible. Oh, and use the stuff I built from Yuriy's schematics (TouchDRO)

Funny how fast time just goes by... I built this back in September of 2015!!! All this time it has been sitting on a shelf in my office...

Funny how fast time just goes by... I built this back in September of 2015!!! All this time it has been sitting on a shelf in my office...

Last edited:

- Joined

- Aug 6, 2015

- Messages

- 3,873

- Joined

- Aug 6, 2015

- Messages

- 3,873

- Joined

- Aug 6, 2015

- Messages

- 3,873

Talk about great packing for shipping these heavy items. Great job there @mattthemuppet2 !!

Yes, those tubes are bolted to the wood... I am telling you... this was not going anywhere!

Yes, those tubes are bolted to the wood... I am telling you... this was not going anywhere!

- Joined

- Sep 28, 2013

- Messages

- 4,305

Awesome! I'm glad they got there safe and sound

- Joined

- Jul 6, 2022

- Messages

- 498

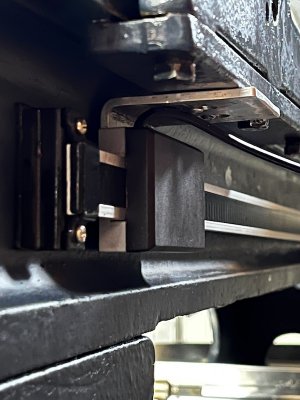

Fixed the bracket... sharper edge now and slotted the holes for allowing adjustment...

View attachment 418933

View attachment 418934

View attachment 418935

Now that I know where it will end... I can trim the bracket and avoid it from extending... not that I have to...

View attachment 418936

Now to drill and tap for the end holders of the scale...

View attachment 418938

Nice! I’ve been doing the same to my lathe today. Same iGaging and touchDRO package.

Sent from my iPhone using Tapatalk