-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Logan 820 Lathe Journey

- Thread starter wachuko

- Start date

- Joined

- Aug 6, 2015

- Messages

- 3,862

Got the materials and casters to make the cart for the toolbox... going with 2" metal casters that should hold the weight well. Trade-off is that these casters have no brakes... I do not think that will be a big deal. I can always insert something in them to keep them from moving.

And forgot to place photos of the lamp here...

After completing the wiring... all done...

And used the wood lathe for the first time, to make the wood handwheel for the 3C collet drawbar... it was an impulse... I was planning on using some exotic wood as my first project for this... well... we are at the house in Ocala and were working on another raised planter... some treated 2x6 scraps were laying around... So I rolled the Delta lathe outside and gave it a try...

Funny, because I started with a 5-1/2"x5-1/2" square and quickly realized, after chunks of wood were flying by me, that I needed to cut as much as I could with the circular saw BEFORE using the lathe... after getting close to the circumference with the saw, then I went back to the lathe... much much much smoother to work it... orientation of the wood grain also played a part... had to flip it around as well.... It was a great learning experience...

Need to apply some wood stain, build a center hub for it and install it!

And forgot to place photos of the lamp here...

After completing the wiring... all done...

And used the wood lathe for the first time, to make the wood handwheel for the 3C collet drawbar... it was an impulse... I was planning on using some exotic wood as my first project for this... well... we are at the house in Ocala and were working on another raised planter... some treated 2x6 scraps were laying around... So I rolled the Delta lathe outside and gave it a try...

Funny, because I started with a 5-1/2"x5-1/2" square and quickly realized, after chunks of wood were flying by me, that I needed to cut as much as I could with the circular saw BEFORE using the lathe... after getting close to the circumference with the saw, then I went back to the lathe... much much much smoother to work it... orientation of the wood grain also played a part... had to flip it around as well.... It was a great learning experience...

Need to apply some wood stain, build a center hub for it and install it!

Last edited:

- Joined

- Oct 7, 2020

- Messages

- 2,109

Looks like you're building yourself kind of a museum piece. Looks very nice!

- Joined

- Aug 6, 2015

- Messages

- 3,862

Thank you, but far from making it a museum pieceLooks like you're building yourself kind of a museum piece. Looks very nice!

I have decided to sell the HF 9”x20” as soon as I am done. Two lathes will be more than enough for this newbie.

- Joined

- Apr 23, 2013

- Messages

- 1,000

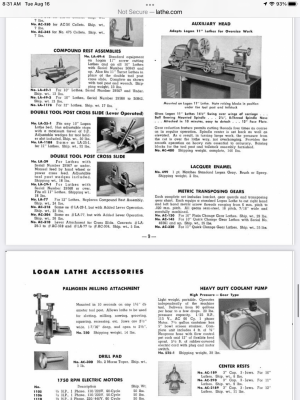

The rectangular part in your pics is a production cross slide. It makes it easy to put a tool on the front and backside of the lathe. It is easy to change from the standard cross slide to the production slide. Many people say production slides are less apt to chatter then the standard compound slide. I started machining in 1953 with a new Logan that was set up with the production slide. And I still prefer it to the standard slide. I didn’t see the gib for the production slide in the pic.

- Joined

- Apr 23, 2013

- Messages

- 1,000

Logan made 2 production cross slides 1 had a lever and the other used the cross slide screw. Both had a hard stop you could use if wanted.Thank you.

I will post it on the Logan Yahoo group to see if I get confirmation... will report back.

It does have a nut... I will take better photos and measure it to add to the description...

Attachments

- Joined

- Apr 23, 2013

- Messages

- 1,000

You can insert brass tips if you want. Also use roller bearings if you want . Some people don’t like the roller bearings because chips can get under them and mark parts. But you can build a chip shield out of cardboard to stop that.Using this duplicate post to add some progress…

View attachment 414412

Almost done…

View attachment 414413

But I thought those fingers needed to be brass so the would not damage/mark the workpiece… These are steel…

- Joined

- Aug 6, 2015

- Messages

- 3,862

I will look for the gib in the other stuff the previous owner gave me… but I think that the gib is missing…The rectangular part in your pics is a production cross slide. It makes it easy to put a tool on the front and backside of the lathe. It is easy to change from the standard cross slide to the production slide. Many people say production slides are less apt to chatter then the standard compound slide. I started machining in 1953 with a new Logan that was set up with the production slide. And I still prefer it to the standard slide. I didn’t see the gib for the production slide in the pic.