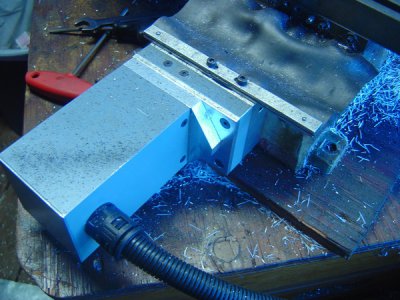

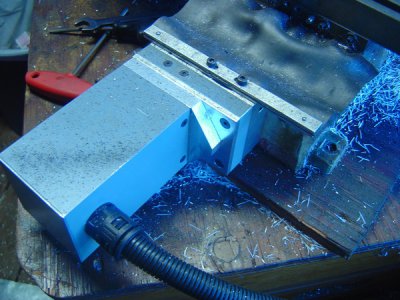

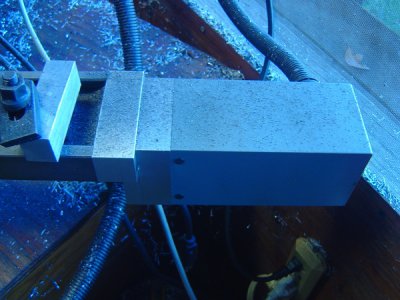

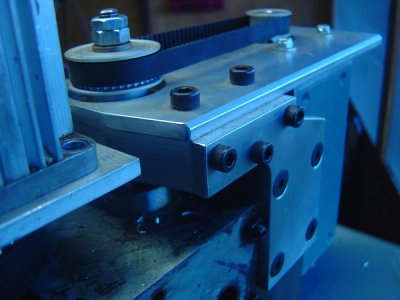

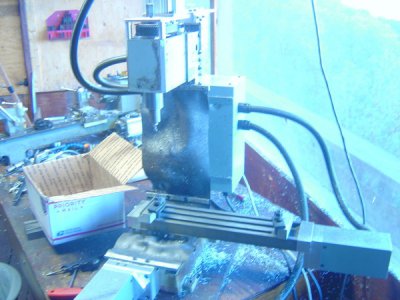

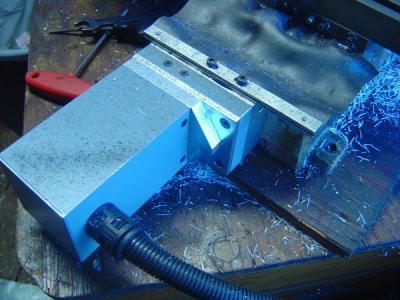

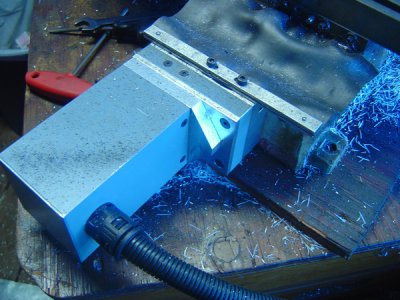

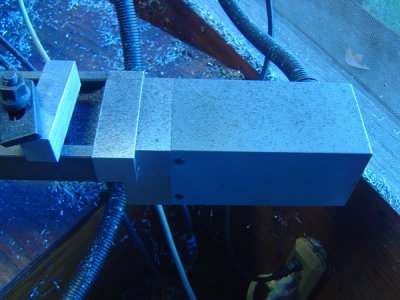

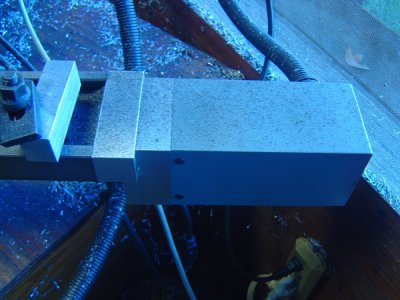

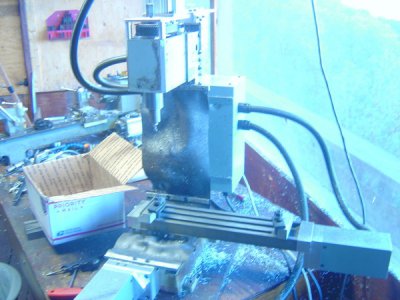

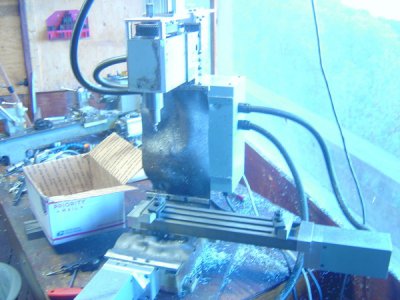

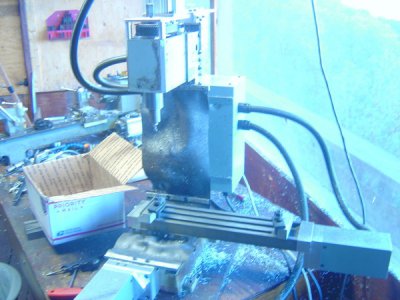

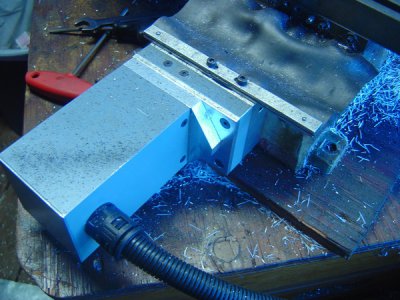

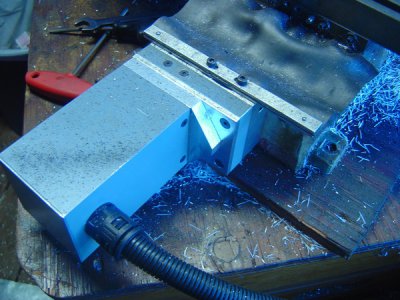

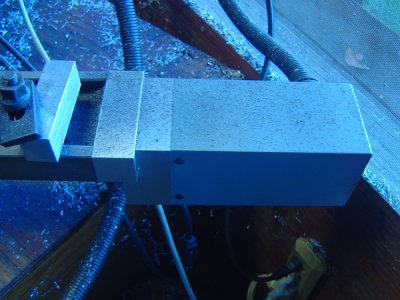

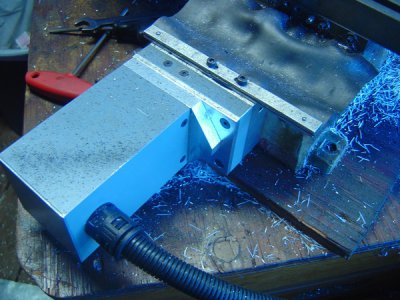

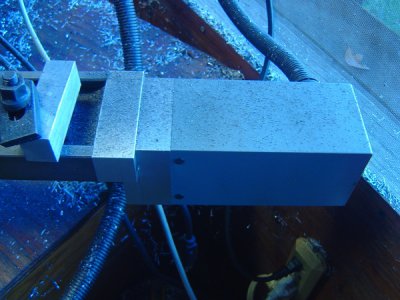

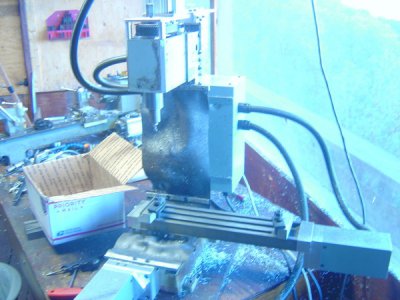

hi everyone. i built a cnc mini x2 a while back and got addicted to cnc. started out with mach3 and quickly abandoned it for linuxcnc (way better!). now i had the urge to convert my mini lathe to cnc as well. first, here are some images of the mini mill im using to do the cnc of the lathe. i never made a build thread for the mill(sorry). i designed my mill conversion using draftsight drawing software. i have some crude drawings if anyone is interested in "plans" (if you can call them that). it is made to be standalone with only power and one parallel port connection. no separate electrical box floating around. the motors are also fully enclosed in aluminum square tube and all wiring is in conduit.

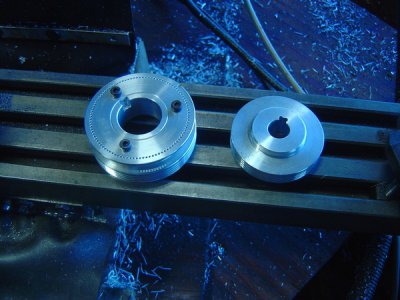

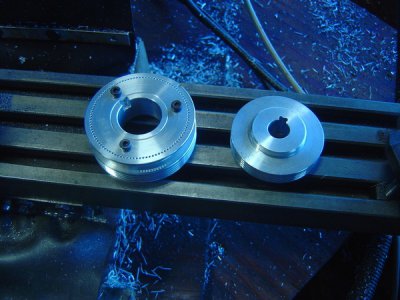

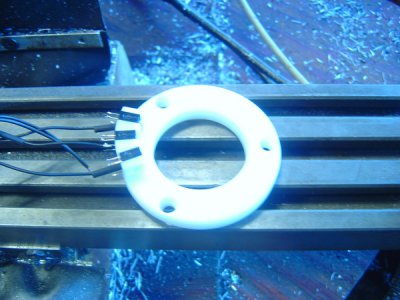

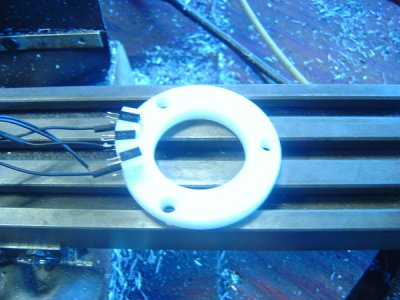

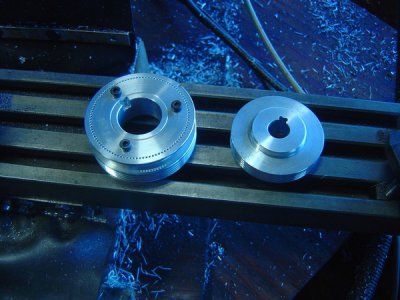

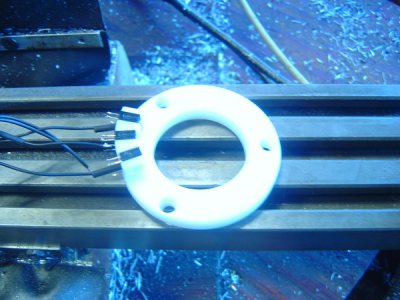

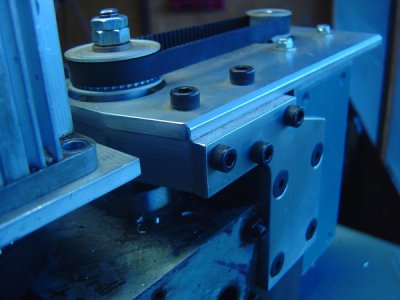

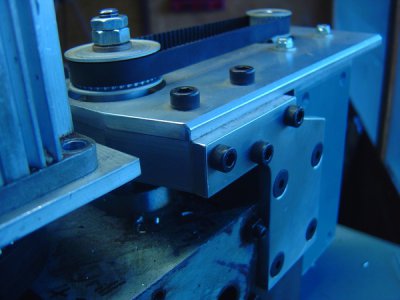

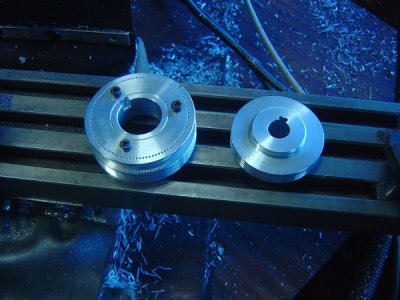

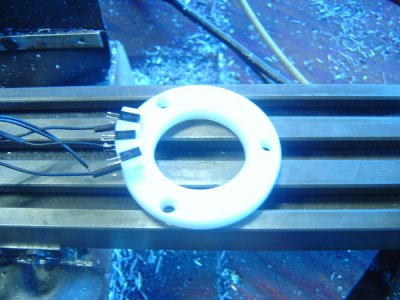

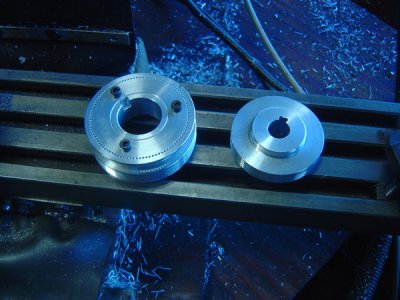

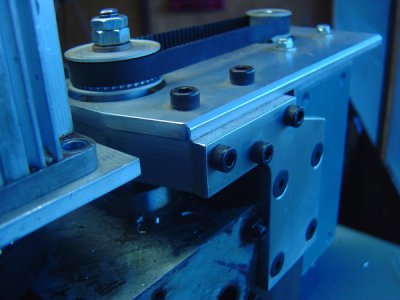

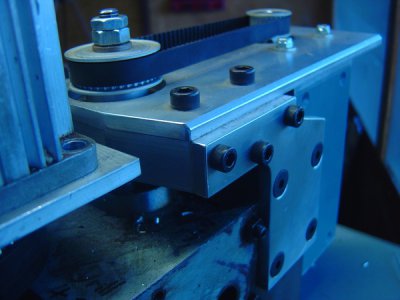

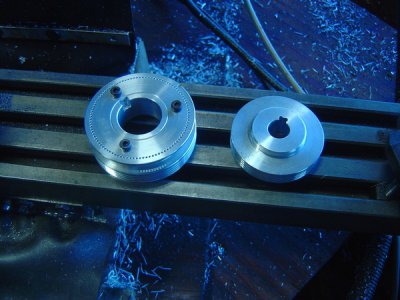

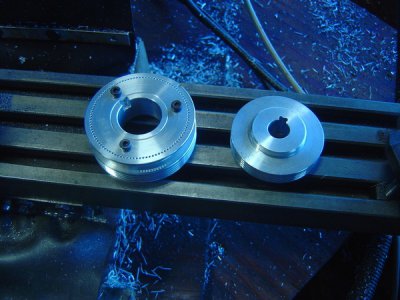

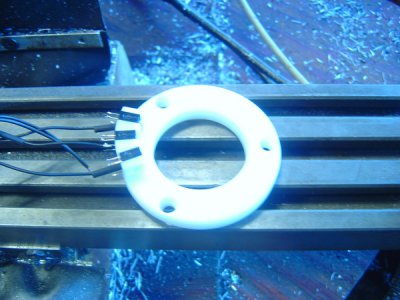

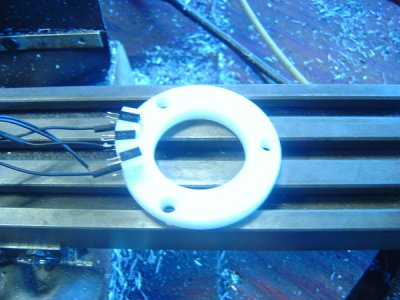

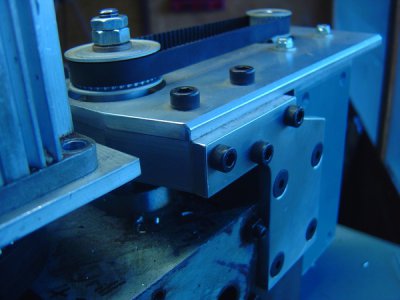

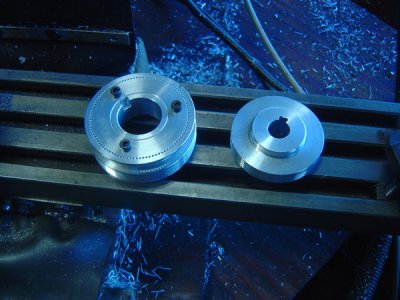

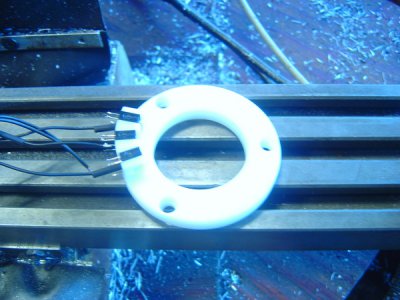

working on a new spindle pulley setup with an encoder for rigid tapping.

now onto the lathe.

it is being designed in fusion 360(awesome). i decided to have a go at making a new cross slide for more travel and t slots, so my design wont really work with a stock cross slide (FYI incase anyone wants to use the design for their own lathe.) i also tucked the x axis stepper under the carriage for more compact lathe.

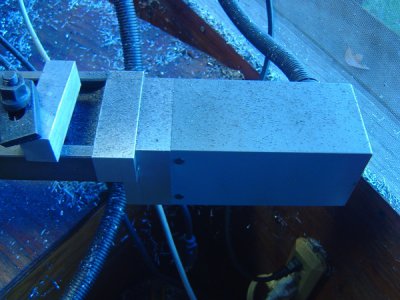

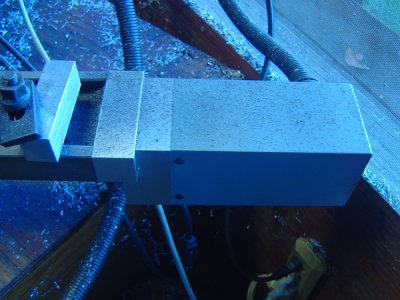

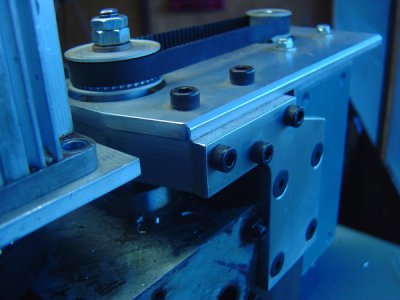

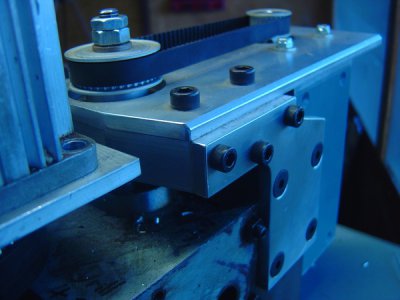

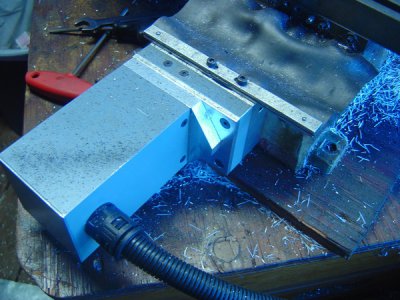

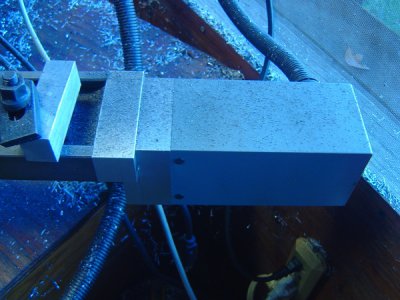

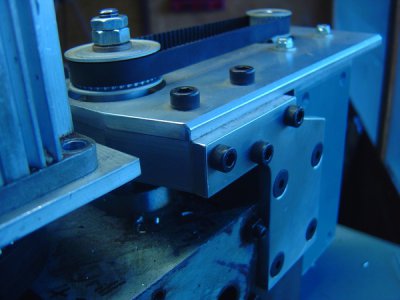

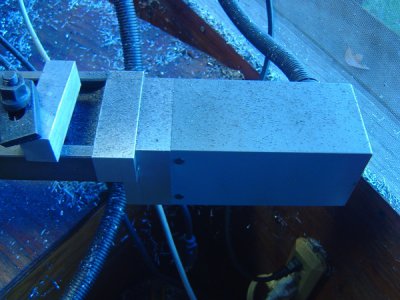

here is the x axis bearing block mounted to the motor plate. the profile was 3d milled to match the motor plate and belt cover.

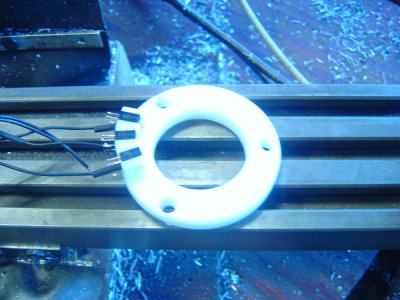

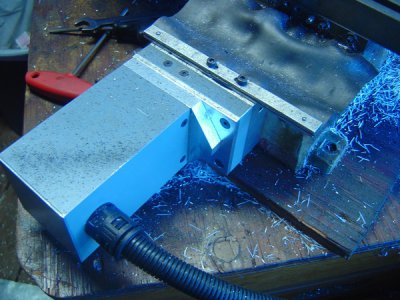

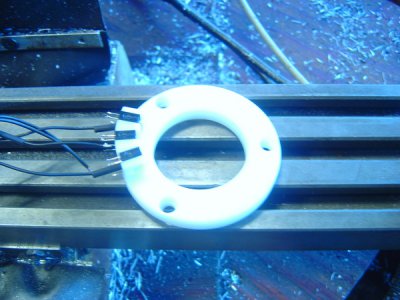

belt cover, made from HDPE. the little aluminum spacers are cnc milled.

collection of parts.

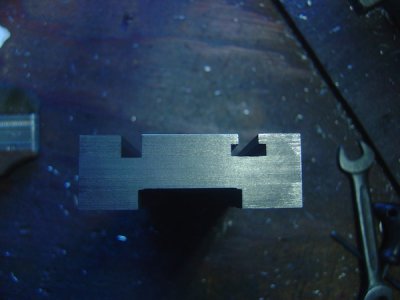

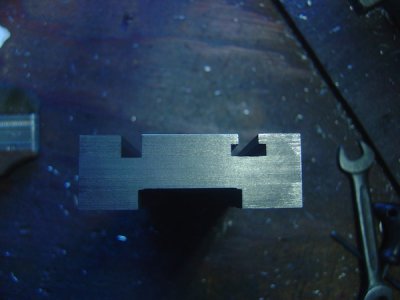

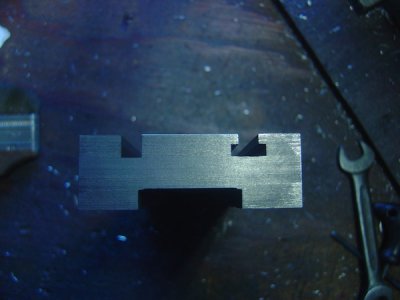

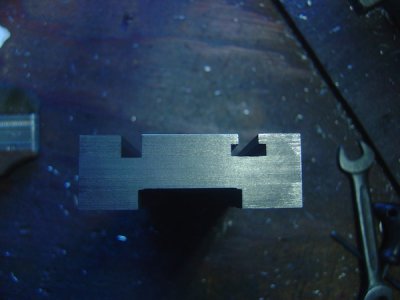

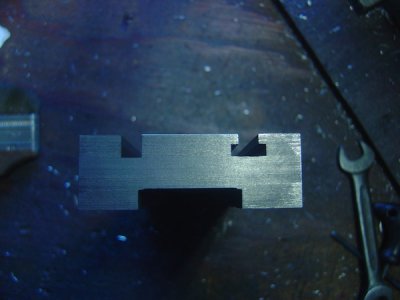

i started on the cross slide. it is made of a chunk of continuous cast iron. i roughed it out at work on a bridgeport clone. it could be done on a mini mill, but would be hard. this is the hardest part of the build i think. did one t slot on my cnc mill so far using a woodruff cutter. the tool is still in one piece luckily. the top side is at finished dimensions. i left a but of extra stock on the bottom to face off when i do the dovetails.

you can download the fusion 360 cnc lathe model from grabcad.

https://grabcad.com/library/cnc-mini-lathe-conversion-1

working on a new spindle pulley setup with an encoder for rigid tapping.

now onto the lathe.

it is being designed in fusion 360(awesome). i decided to have a go at making a new cross slide for more travel and t slots, so my design wont really work with a stock cross slide (FYI incase anyone wants to use the design for their own lathe.) i also tucked the x axis stepper under the carriage for more compact lathe.

here is the x axis bearing block mounted to the motor plate. the profile was 3d milled to match the motor plate and belt cover.

belt cover, made from HDPE. the little aluminum spacers are cnc milled.

collection of parts.

i started on the cross slide. it is made of a chunk of continuous cast iron. i roughed it out at work on a bridgeport clone. it could be done on a mini mill, but would be hard. this is the hardest part of the build i think. did one t slot on my cnc mill so far using a woodruff cutter. the tool is still in one piece luckily. the top side is at finished dimensions. i left a but of extra stock on the bottom to face off when i do the dovetails.

you can download the fusion 360 cnc lathe model from grabcad.

https://grabcad.com/library/cnc-mini-lathe-conversion-1