Ok, I've only built one shop, a 40'x60' commercial building. I've had others and currently work out of our garage, here are my thoughts.

1. Make it bigger - incremental cost of a larger building is small compared to expanding later. If cost is an issue now go higher and make one of the walls strong enough to attach a lean-to later. Go as high as you can since wall space up high can be great for storage with pallet racking and a possible loft, as others have said an 8' roll-up door is going to be a serious limitation. If you know you're never going to work on bigger projects you can go with something that will fit the tools you have now but what if your wife wants you to restore a vintage travel trailer? With no zoning limitations I'd go for something like a 40x60 and leave half of it unfinished if needed.

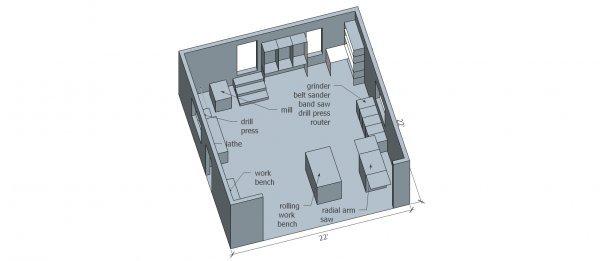

2. Separate areas are a great idea, put a roll up door on the metal shop so you can get equipment in/out and can work with it open on nice days. Also this will allow you to run multiple mini-split AC units so you can only cool the area you're working in at the time.

3. Compressor, RPC, dust collector should all live outside. A small lean-to will keep them out of the elements and the heat really shouldn't bother them. Definitely consider electrical runs while building to ensure the shortest distance for high current tools. You may also want to run some conduit through the floor before you pour the slab, it's awfully nice to be able to power equipment that's in the middle of a space from an outlet right there rather than having to drop down from the ceiling or have extension cords on the floor.

4. Absolutely stub in plumbing for a bathroom with a shower, you will be glad you did.

5. An office isn't a bad idea either. It will give you an area to plan and keep books, computers, drawings, etc. out of the way of your tools.

If this is your "forever home" then do it once and do it right. It's fairly easy to modify a steel building or pole barn after it's built but making it bigger is more difficult. You probably already know that your wife will have stuff she wants to store and maybe even a hobby area of her own, I'e never heard someone say they wish their shop was smaller....

Cheers,

John

I agree with what you are saying. I would go as big as you absolutely can afford now. I am looking at a 50x80 steel building, 16 foot walls, which will keep everything out of the weather. I would also add in-floor heat that runs off the hot water heater and a circulation pump and a few zones. you want 4" of insulation under the concrete and 8" in the walls if you have the room and 18" in the ceiling. Ceiling fans in each area.

Concrete needs to be thick and lots of rebar, 6" minimum if you dont want it to move with your machines on it, 12" directly under the machines if possible. Air conditioning also keeps the moisture down. I would also add an area for pallet racking, I have a horizontal compressor that I put on top of it then I can still put stuff underneath it. Allow room for an air dryer, it will help with the plumbing for air lines later on.

Power needs to be adequate for multiple machines in multiple locations, if you can find some, run a wire way that is enclosed, then you just drop the 120/220/3ph where you need it with a down drop. I have 6 different 220 outlets in a 20/40 shop along just one wall, I am planning on adding a few along the opposite wall.

LED lighting, 8' T12's are no coming down in price, enough to be cost effective and provide a lot of light. I would also paint the floor white, and use steel for the lower portion of the walls, if you ever weld, it can be a building saver. Just use the same type of material that the outside of the building but use white. The white walls and floor will help with light, especially at lower levels.

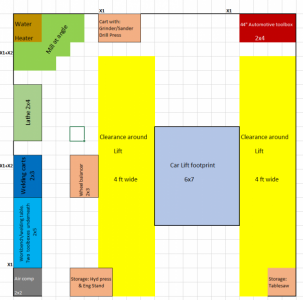

If you want a car lift, you want to put sonotubes down to support the lift, I guy I worked with had his fall over with a Ford 3/4 ton on the lift, anchors pulled out of the floor. No rebar on the anchors either...

This part of the criteria for my ultimate shop, I will also add a second floor with my library and storage with a small gantry crane to load and unload the upper level for about 8-12 feet across one end.