- Joined

- Nov 24, 2013

- Messages

- 254

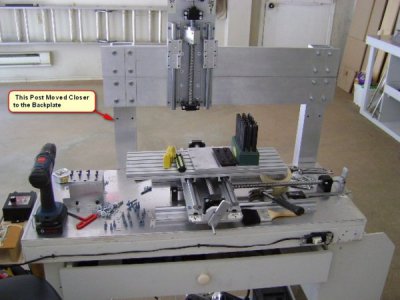

I’m approaching the end of my new Lathe / Mill combo and the attached 2 pictures shows what I have done so far. I have no idea if this is going to be a successful project since I never had a mill before and the Taig mini Lathe I got recently was frustrating too small for any work.

Since I have no experience in machining I’m looking for any comments / ideas regarding the layout.

The Z axis is done and at the picture is at its lowest position. The travel to the top is 8”

The table top is 16”x40”

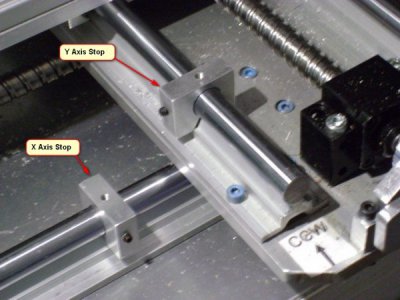

The X and Y axes are not done and lay on the table top now trying to figure out their best position.

The support of the Lathe headstock which at the picture sits on top of 3 pcs of 2”x4” is not done because I have to finish the X & Y axes first to establish the bed height. I also wonder if there is any advantage to move the Lathe headstock further to the left.

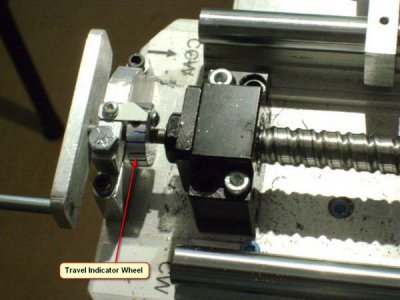

The ends of the X & Y ball screws are long for a purpose. I have order some handles which will fit there but I don’t know the exact width of these handles. After I receive the handles I will trim these ends

Thank you

Since I have no experience in machining I’m looking for any comments / ideas regarding the layout.

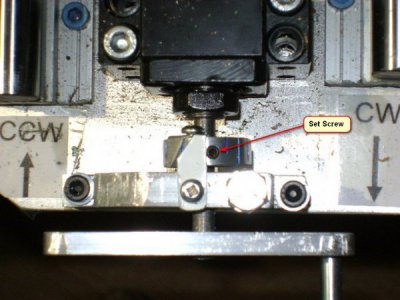

The Z axis is done and at the picture is at its lowest position. The travel to the top is 8”

The table top is 16”x40”

The X and Y axes are not done and lay on the table top now trying to figure out their best position.

The support of the Lathe headstock which at the picture sits on top of 3 pcs of 2”x4” is not done because I have to finish the X & Y axes first to establish the bed height. I also wonder if there is any advantage to move the Lathe headstock further to the left.

The ends of the X & Y ball screws are long for a purpose. I have order some handles which will fit there but I don’t know the exact width of these handles. After I receive the handles I will trim these ends

Thank you