-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My PM-940 CNC Modifications

- Thread starter cut2cut

- Start date

Thanks for the pic!

Think I'm going to do the bearings at the same time... I'm thinking AC bearings will be better for the PDB.

PZ

Yeah, I was wondering if the site was causing huge issues , or you were having huge issues with the belt conversion. Actually, that part is significantly easier and less stressful than replacing the bearings in the spindle, imho.

Think I'm going to do the bearings at the same time... I'm thinking AC bearings will be better for the PDB.

PZ

If you are into VFD and motor settings especially for rigid tapping, you can join or follow along in this other thread.

https://www.hobby-machinist.com/threads/motors-minimum-rpm-wrt-rigid-tapping.66280/

Cheers,

Jake

https://www.hobby-machinist.com/threads/motors-minimum-rpm-wrt-rigid-tapping.66280/

Cheers,

Jake

Last edited:

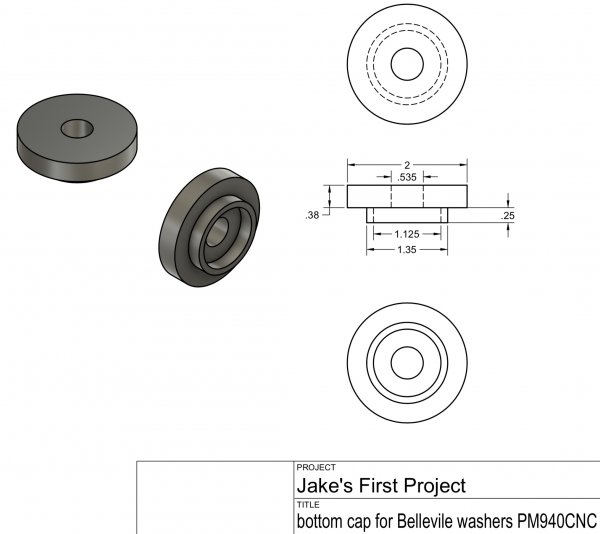

Ok, long time, no see ! Well, here we go, POWER DRAW BAR TIME ! I've collected a bunch of the necessities and now need to mill the parts. I am in need of someone that can make a steel "top hat" for the belleville washers since I don't have a capable lathe and not much experience with it either ! So anyone out there, please let me know if its in your wheel house and can do it for me !? ( see attached drawing ( in inches ))

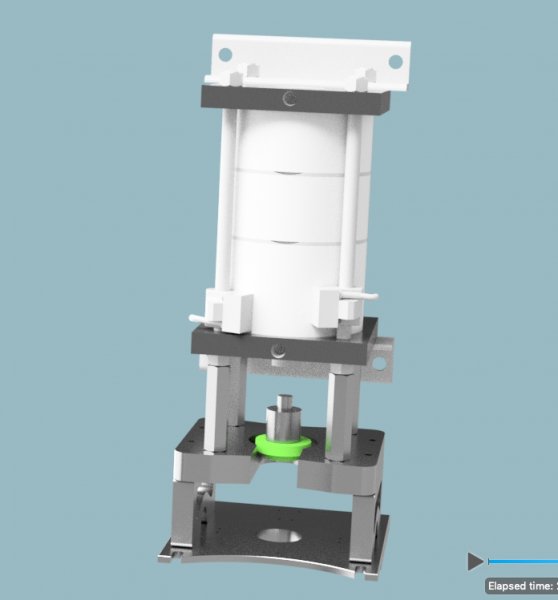

I'll be posting details later today but here is the render of the model. Its adding some weight to the head, so I'll be using struts on the head to take some of the load away. Details to come !

Cheers,

Jake

I'll be posting details later today but here is the render of the model. Its adding some weight to the head, so I'll be using struts on the head to take some of the load away. Details to come !

Cheers,

Jake

Welp, this Power Draw bar project has been kicking my ass. I think I have an issue with my Z axis stepper which I'm in the middle of trouble shooting. So its putting the possibility of me upgrading to DMM servos to the forefront. ( Phazer, calm down.... Don't eat that popcorn too fast, I wouldn't want to be the reason for you untimely demise !

So, my question is, is it worth the extra money to go for DYN4 drivers, or just go with the cheaper, and less powerful DYN2 drivers ? Also wondering if the 750Watt will be adequate for the Z or will I regret it. Likely I'll add a counterweight as the gas struts I just added don't seem to be doing the trick so that would help a lot. It is still possible I could be facing a g-code gremlin. I will say, my Z axis has always been noisy and the Z ball screw has a whip to it so there are many things that could be adding up to my Z issues. I'm tempted to also buy a Z axis double nut kit from ArizonaVideo but really wouldn't look forward to installing it. That PM940 column and head is heavy and tough to deal with. Alas, servos are the way to go so I figure I may as well go for it now and enjoy the benefits regardless of what the real issue is with the Z.

Jake

So, my question is, is it worth the extra money to go for DYN4 drivers, or just go with the cheaper, and less powerful DYN2 drivers ? Also wondering if the 750Watt will be adequate for the Z or will I regret it. Likely I'll add a counterweight as the gas struts I just added don't seem to be doing the trick so that would help a lot. It is still possible I could be facing a g-code gremlin. I will say, my Z axis has always been noisy and the Z ball screw has a whip to it so there are many things that could be adding up to my Z issues. I'm tempted to also buy a Z axis double nut kit from ArizonaVideo but really wouldn't look forward to installing it. That PM940 column and head is heavy and tough to deal with. Alas, servos are the way to go so I figure I may as well go for it now and enjoy the benefits regardless of what the real issue is with the Z.

Jake

Well, I'm equally excited to watch some DMM servos get hooked up to a 940!!

I think the Leashine 86HS85 stepper on our Z axis actually only produces about 2-3 nm of torque at the speeds and resolution we run it at... So I would want something better than that on my Z. I've been thinking a 1.0 KW or even the 1.3 KW and don't worry about a counter weight. or gas struts. Though I also want my Z to be able to move at least 100 ipm, preferably even faster. I would also do 0.75 KW drives on my X and Y... I'd rather have too much than end up wishing I had bigger motors later.

As for DYN 2 vs 4... i'd go with 4. They can be programmed to turn an output on if they loose position, which would be very nice. Also, they run on 240 VAC, so there is no need for a big DC power supply, which nice for a few reasons. Not only does that mean less wiring, but it means more room freed up in the cabinet. Only thing that might mess that up is the 24 VDC holding break... not sure if needs an external 24 VDC. I'll have to do some more reading on it. Please keep in mind that I have priced NONE of this out, I have only read spec sheets and am dreaming big.

PZ

View attachment 280498

Well, I'm equally excited to watch some DMM servos get hooked up to a 940!!

I think the Leashine 86HS85 stepper on our Z axis actually only produces about 2-3 nm of torque at the speeds and resolution we run it at... So I would want something better than that on my Z. I've been thinking a 1.0 KW or even the 1.3 KW and don't worry about a counter weight. or gas struts. Though I also want my Z to be able to move at least 100 ipm, preferably even faster. I would also do 0.75 KW drives on my X and Y... I'd rather have too much than end up wishing I had bigger motors later.

As for DYN 2 vs 4... i'd go with 4. They can be programmed to turn an output on if they loose position, which would be very nice. Also, they run on 240 VAC, so there is no need for a big DC power supply, which nice for a few reasons. Not only does that mean less wiring, but it means more room freed up in the cabinet. Only thing that might mess that up is the 24 VDC holding break... not sure if needs an external 24 VDC. I'll have to do some more reading on it. Please keep in mind that I have priced NONE of this out, I have only read spec sheets and am dreaming big.

PZ

The sales guy at DMM has been very helpful. I asked about DYN2 vs DYN4. Basically the DYN2 drive powered by our existing 48VDC power supply with their 86M-DHT .75kW servo would run at 1200rpm. With our 5 turn per inch ball screws that equals 240 ipm. ( I could be wrong and our big DC power supply provides 60VDC ? which would give us 300 ipm ) Basically speed is directly related to the voltage. The DYN4 drives apparently double the speed by being 220/240 V AC but they have no other performance advantage over the DYN2 other than top speed. They both have the same holding and "cutting" power. I perceive this as being that the motor is the limitation, not the speed control, however voltage dictates rpm, so the DYN4 has the advantage of 220v AC but if you don't intend to go faster than 240 ipm, I am told there is no advantage. I, however, have opted for the DYN4 due to exactly what you said Phazer, being able to remove the existing big DC power supply and basically a cleaner wiring and if ever, being able to use the equipment being more versatile if used on another setup. The DYN4 drives are fairly large, so its almost a necessity to fit them in the existing cabinet. I do plan to add a counter weight, but regardless, will also pay the hefty cost for 24v brake option as added insurance if the counter weight ever should fail it could really result in a nasty crash. The added benefit of adding a Z counter weight, is that I will be able to get the .75kW ( 750watt ) motor for all three axis. Also, they have servo motors with 14mm shafts, so it should basically drop right into our pm940cnc with little to zero fuss as the 4 mounting holes are with 2mm ( on the diagonal ) of being correct, I don't see this as being a "show stopper" however could require some small modification to the servo motors to make it fit.

However, if you go with the "N" version ~ 86N-DHT the bolt pattern is exactly the same so it drops right in with only one issue, the shaft is 1/2 inch, which requires different shaft couplers / "lovejoy" couplers. I think VXB bearings has the shaft couplers needed for $50 each. ( Correct me if I'm wrong, but I measured 14mm on the motor side and 16mm on the Ball screw, at least on the X axis. ) If they are 14x14 then they can be found much much cheaper on ebay but expect them to take longer to arrive from China. All in all, the DYN4 DMM Servo setup should cost around $1500 to $2000. A few hundred less if you go with DYN2.

attached is what I milled last night, one of two for the PowerDraw bar project.

ok, enough for now, gotta join the thanksgiving festivities...

Cheers,

Jake

One other note, at least on my machine, the power supplys are just transformers. The Stepper drives run off 60VAC, which means I would need to get a big DC power supply if I wanted to run DYN2 drives. The smaller of the two transformers just provides 24 VAC for all the Chinese control circuitry.

PZ

PZ