I can’t see it being a horizontal mill. The head doesn’t have the rigidity that a horizontal has. Just a guess but that sure looks like a tool and cutter grinder. Head looks like it’ll swivel. The one accessory pictured is a indexer which would be used in grinding. The table and functions look exactly like my t&c grinder. Mystery is spindle attachments? Accepts a collet or spindle. My bet is t&c grinder.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mystery Horizontal Mini Milling Machine (Northern Illinois Machinists LMG-3) made in USA?

- Thread starter 9t8z28

- Start date

I think I see what you mean by the head swiveling. It does look as if it has the capability to swivel. If it didn’t have the capability to swivel I would expect there to be a joint there but I might be totally wrong because I’ve never seen one of these in person before. I hope it’s a T&CG !

The good news is that I am going to go take a look at it but the owner is not available until Wednesday. Hopefully no one sneaks in an appointment with this guy and snatches it up before me.

The good news is that I am going to go take a look at it but the owner is not available until Wednesday. Hopefully no one sneaks in an appointment with this guy and snatches it up before me.

I can’t see it being a horizontal mill. The head doesn’t have the rigidity that a horizontal has. Just a guess but that sure looks like a tool and cutter grinder. Head looks like it’ll swivel. The one accessory pictured is a indexer which would be used in grinding. The table and functions look exactly like my t&c grinder. Mystery is spindle attachments? Accepts a collet or spindle. My bet is t&c grinder.

Oh, gotcha. And you know what, I now see where the arm for the spindle mounts. Right on top of what looks to be a lathe compound.

It looks like a lathe compound.....

What is the typical rpm of a surface grinder today ? I will Google search the words you used and see if I can find any like this one.

I agree with you about the collets. They do appear to be brown and sharpe #7 collets. I can’t see how a 5C would come close to fitting at all.

He does show an over arm in the pictures on craigslist, or what he is referring to a over arm. It’s slotted so it looks like it allows the head to be adjusted up and down. I asked the owner a few questions about travel of each axis and this is what he said :

“Hi Brandon this is (****), the guy selling the horizontal mill. Just got back and saw your emails. I think the travel on the x axis with the rack feed is about 11 inches of usable travel. I think the table is 16 inches long. The y travel has micrometer feed with acme screw it has somewhere around 6 in of travel. The z axis ( vertical) is about six inches of travel”

I agree with you about the collets. They do appear to be brown and sharpe #7 collets. I can’t see how a 5C would come close to fitting at all.

He does show an over arm in the pictures on craigslist, or what he is referring to a over arm. It’s slotted so it looks like it allows the head to be adjusted up and down. I asked the owner a few questions about travel of each axis and this is what he said :

“Hi Brandon this is (****), the guy selling the horizontal mill. Just got back and saw your emails. I think the travel on the x axis with the rack feed is about 11 inches of usable travel. I think the table is 16 inches long. The y travel has micrometer feed with acme screw it has somewhere around 6 in of travel. The z axis ( vertical) is about six inches of travel”

If it is an adaptation of a surface grinder the handle at the top of the column should have a dial with graduations of .0001". The dial for the Y control handle should have graduations of .001" or .002". As Mark said this machine does not have the pulley ratio for grinding. Grinders of this era were fixed at 3,600 rpm + or- a few rpm.

Some of the smaller benchtop horizontal mills didn't have an over arm. There is currently a Burke #1 and a Goodell Pratt on eBay that don't have over arms. The Goodell Pratt table is at a fixed height with the head being able to be raised and lowered by the crank at the back of the machine. Given the age of the machine you are looking at I believe it is and always was a horizontal mill. I also googled "antique bench top horizontal milling machine" and found several images of similar size machines without an over arm.

Burke:

https://www.ebay.com/itm/Early-Burke-Horizontal-Milling-Machine-No-1/292670008749?hash=item44247dedad:g:I2MAAOSwk1NbaAx0&_pgn=1&_sacat=0&_nkw=horizontal+milling+machine&_from=R40&rt=nc&LH_TitleDesc=0|0

Goodell Pratt:

https://www.ebay.com/itm/Vintage-Goodell-Pratt-No-644-Miller-Horizontal-Bench-Top-Milling-Machine-refurb/202311081530?hash=item2f1aae1e3a:gX0AAOSwUQlavQYP:sc:FedExHomeDelivery!53711!US!-1&_pgn=2&_sacat=0&_nkw=horizontal+milling+machine&_from=R40&rt=nc&LH_TitleDesc=0|0

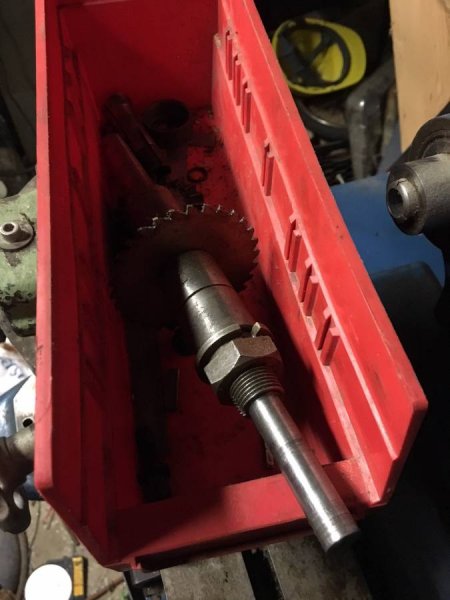

I don't believe the collets are 5C. They may be 2S or 3C, both of which I believe go up to 9/16". The 5C collets need a bore large enough to handle a collet that will accept 1 1/8" stock. Looking at the picture of the collet in hand I can't believe the body is big enough to accept 1 1/8" stock. Also note the arbor which is .750" where the cutters fit, but probably no larger than .500" where it enters the collet.

- Joined

- Apr 14, 2014

- Messages

- 3,135

I can’t see it being a horizontal mill. The head doesn’t have the rigidity that a horizontal has. Just a guess but that sure looks like a tool and cutter grinder. Head looks like it’ll swivel. The one accessory pictured is a indexer which would be used in grinding. The table and functions look exactly like my t&c grinder. Mystery is spindle attachments? Accepts a collet or spindle. My bet is t&c grinder.

All horizontal mills I am aware of can accept either a spindle or collets. My US Machine Tool mill has a B&S #9 taper. It came with several B&S #9 collets to hold end mills and slitting saw arbors.

- Joined

- Nov 23, 2017

- Messages

- 1,191

He forgot to post the most important pictures..... I don't think its a grinder.......

https://philadelphia.craigslist.org/tls/d/small-horizontal-milling/6662951956.html

https://philadelphia.craigslist.org/tls/d/small-horizontal-milling/6662951956.html

You’re right, I did not post all of the pictures because I thought it would be too much to download. I figured anyone interested in seeing it would click on the link. Sorry, my bad

He forgot to post the most important pictures..... I don't think its a grinder.......

https://philadelphia.craigslist.org/tls/d/small-horizontal-milling/6662951956.html

View attachment 273962

View attachment 273963

- Joined

- Jan 2, 2016

- Messages

- 1,953

I did click, and look. I guess I just focused on the handle. Never seen any mill with one, but with the descriptions, it makes sense.

Yeah after seeing them pieces it’s definately a mill.  I think of a overhead arm to support the arbor spindle on a horizontal.

I think of a overhead arm to support the arbor spindle on a horizontal.

I would still think it could be used as a t&c grinder. Adapt a wheel to a homebrew arbor. Shouldnt be hard runout can be taken care of with dressing stone. Grinding wheels usually have a 3600rpm limit. So if you can spin that thing at least 3k you should be alright.

I would still think it could be used as a t&c grinder. Adapt a wheel to a homebrew arbor. Shouldnt be hard runout can be taken care of with dressing stone. Grinding wheels usually have a 3600rpm limit. So if you can spin that thing at least 3k you should be alright.