- Joined

- Nov 16, 2012

- Messages

- 5,596

After hitting the other side of the grove with the surface grinder, now I'm fitting the V-groove. Before doing anything, I ran a file over the ground surfaces to get rid of some chatter marks. The wheel I "sacrificed" to put a 45[SUP]o[/SUP] angle on is an extremely hard wheel -and hard wheels chatter like crazy. The initial fit was quite good with no wiggle but needed a good bit of tweaking. I checked flatness of the bed plate with a DI mounted on the crossfeed and then I discovered the v-groove had to be cut a little deeper -back to the SG... With all said and done and a little tweaking it's at about 1 thou from side to side. To fix that, I'll need to take a tiny bit off the flat side of the of the bed plate.

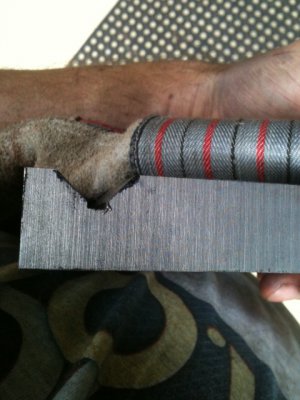

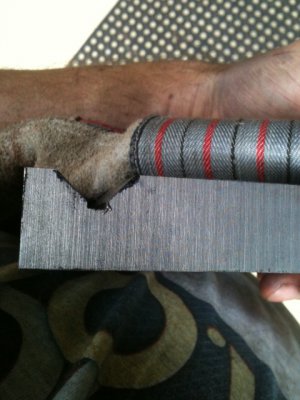

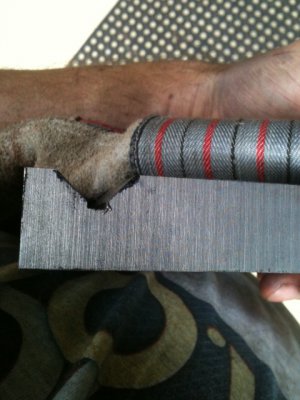

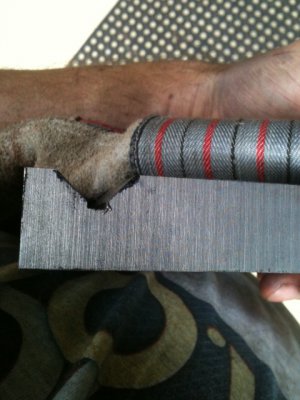

Right now, I'm bluing the all the V's and checking for rub spots. Here you can see some as well as the profile with a top-slot cut in at the root. Later on, I'll put an oil cap on the top side.

Now I know I'm dangerously in "scraping territory" here and I have no clue other than watching Rich's DVD but, this is coming along well. I'm sure you pro guys would just as soon get a rope and hang me but, I took a HSS lathe bit, ground it to serve my needs and pounded a wooden block on the end for a handle. It works-out pretty well. I can go right to those high spots and peel the tops of e'm right off. After that, I hit it with a file, slather with more bluing and try again.

It's a slow process and has taken me 2 hours so far (and about 20 test fits) but, I'd say it's probably 80% of the way there. At some point, I'll have to put some feather-scraping in there for oil... -I'll figure that out when I get there.

Oh, BTW, you can see that Sash thinks this is a very, very boring process. -Poor girl, she hates when I sit for 2 hours and don't give her attention...

Ray

Right now, I'm bluing the all the V's and checking for rub spots. Here you can see some as well as the profile with a top-slot cut in at the root. Later on, I'll put an oil cap on the top side.

Now I know I'm dangerously in "scraping territory" here and I have no clue other than watching Rich's DVD but, this is coming along well. I'm sure you pro guys would just as soon get a rope and hang me but, I took a HSS lathe bit, ground it to serve my needs and pounded a wooden block on the end for a handle. It works-out pretty well. I can go right to those high spots and peel the tops of e'm right off. After that, I hit it with a file, slather with more bluing and try again.

It's a slow process and has taken me 2 hours so far (and about 20 test fits) but, I'd say it's probably 80% of the way there. At some point, I'll have to put some feather-scraping in there for oil... -I'll figure that out when I get there.

Oh, BTW, you can see that Sash thinks this is a very, very boring process. -Poor girl, she hates when I sit for 2 hours and don't give her attention...

Ray