-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need An Electrician L.A. Area Surrounding

- Thread starter Hutch

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,255

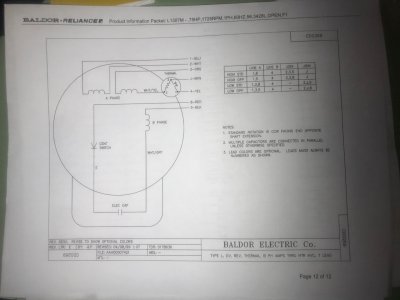

Hutch can you post the nameplate info from your motor and drum switch? I could do a diagram for you and help you get it going, even if you have someone else do the actual wiring

-Mark

-Mark

Thank you, Mark.

Currently,

I have wires 1-3-8 tied together joining post #6

I have wires 2-J-5 tied together going to post # 1

I have the # 4 wire going to post #2, also joined with line 2 neutral.

Line 1 is on post #5 Power

Line 2 in on post #2 Neutral.

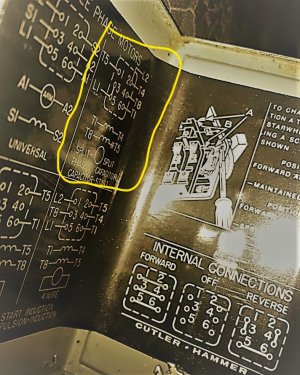

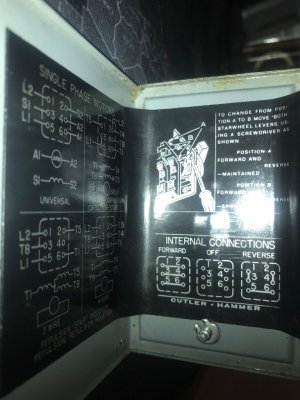

I'm using the diagram with single phase/capacitor start chart.

There looks to be jumper between post # 5 to # 3. But when using a jumper just seem to trip the circuit breaker for the garage.

When I reversed wire 5 and 8 the motor did rotate in reverse but would not rotate forward. So, I know the motor is capable of reversing.

Is it possible I might have fried my drum switch?

I did install a new capacitor.

Thank you for taking the time to help.

Currently,

I have wires 1-3-8 tied together joining post #6

I have wires 2-J-5 tied together going to post # 1

I have the # 4 wire going to post #2, also joined with line 2 neutral.

Line 1 is on post #5 Power

Line 2 in on post #2 Neutral.

I'm using the diagram with single phase/capacitor start chart.

There looks to be jumper between post # 5 to # 3. But when using a jumper just seem to trip the circuit breaker for the garage.

When I reversed wire 5 and 8 the motor did rotate in reverse but would not rotate forward. So, I know the motor is capable of reversing.

Is it possible I might have fried my drum switch?

I did install a new capacitor.

Thank you for taking the time to help.

Attachments

- Joined

- Apr 30, 2015

- Messages

- 11,255

Hi Hutch, give me a little time to cogitate on the pictures and I'll give you a response back. The drum switch diagrams sometimes require a bit of interpretation depending on the motor at hand- they often don't take into account the thermal cutout

I assume you want to run this on 120 volts and not 240?

-Mark

As text: for 120vac:

Line hot to drum 5

Line neutral to motor 4

Motor 1 and 3 to drum 6

Motor J and 2 to drum 1

Motor 5 to drum 2

Motor 8 to drum 3

Connect one jumper drum 4 to 6, no other jumpers needed.

Swap motor 5 and 8 if necessary for correct rotation with respect to drum switch handle- that's it

I assume you want to run this on 120 volts and not 240?

-Mark

As text: for 120vac:

Line hot to drum 5

Line neutral to motor 4

Motor 1 and 3 to drum 6

Motor J and 2 to drum 1

Motor 5 to drum 2

Motor 8 to drum 3

Connect one jumper drum 4 to 6, no other jumpers needed.

Swap motor 5 and 8 if necessary for correct rotation with respect to drum switch handle- that's it

Last edited:

- Joined

- Apr 30, 2015

- Messages

- 11,255

Yes wire it just as I wrote it, should work fine. Extend wires as necessary to reach the drum switch. Just to be clear, the motor wires 5 and 8 are pulled off their current motor terminals and brought out to reach the drum switch. Insulate as required of course with tape or heat shrink tubing if you have it. Double check your connections carefully.

Here's a 240 volt version for you also if you want for future reference--

for 240 vac:

Line 1 to motor 4

Line 2 to drum 5

Motor 1 to drum 6

Motor 2 and 3 to drum 1

Motor 5 to drum 2

Motor 8 to drum 3

Motor terminal J no connection

Install jumper from drum 4 to 6 as before. No other jumpers. Swap 5 and 8 if necessary for rotation.

Here's a 240 volt version for you also if you want for future reference--

for 240 vac:

Line 1 to motor 4

Line 2 to drum 5

Motor 1 to drum 6

Motor 2 and 3 to drum 1

Motor 5 to drum 2

Motor 8 to drum 3

Motor terminal J no connection

Install jumper from drum 4 to 6 as before. No other jumpers. Swap 5 and 8 if necessary for rotation.

Last edited:

Mark, I can't thank you enough. I have reverse. It is for a 120 VAC.

I finally have reverse. Thank you, thank you, thank you.

Maybe one day you can explain what does what in the electrical section. It's all a mystery too me. lol.

I followed your post #5 exactly and it worked.

Just experimenting cutting some metric threads. Perfect.

I'll make the actual parts out of SS tomorrow.

I finally have reverse. Thank you, thank you, thank you.

Maybe one day you can explain what does what in the electrical section. It's all a mystery too me. lol.

I followed your post #5 exactly and it worked.

Just experimenting cutting some metric threads. Perfect.

I'll make the actual parts out of SS tomorrow.

Attachments

- Joined

- Apr 30, 2015

- Messages

- 11,255

Good to hear! It's pretty simple, a split-phase motor can be reversed by swapping the polarity of one of the windings, at start up.

You can thank Nikola Tesla for much of today's motor technology

There's lots of info on the web about AC motors if you want to know more- not enough room here

-M

Be careful not to spin off the chuck using reverse; threadcutting with backgears should be perfectly safe, but at higher speeds there is some risk

You can thank Nikola Tesla for much of today's motor technology

There's lots of info on the web about AC motors if you want to know more- not enough room here

-M

Be careful not to spin off the chuck using reverse; threadcutting with backgears should be perfectly safe, but at higher speeds there is some risk

Last edited: