- Joined

- Sep 3, 2018

- Messages

- 14

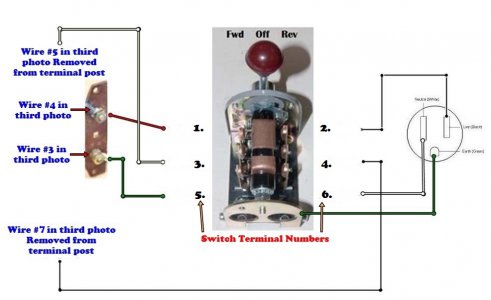

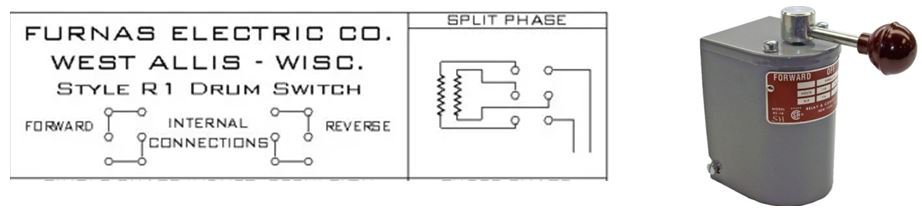

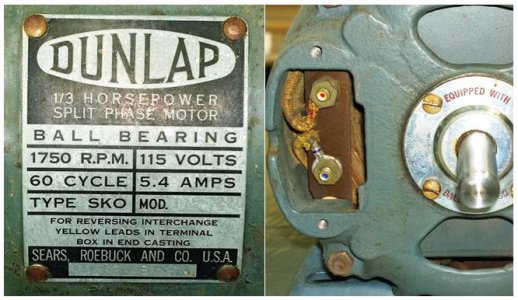

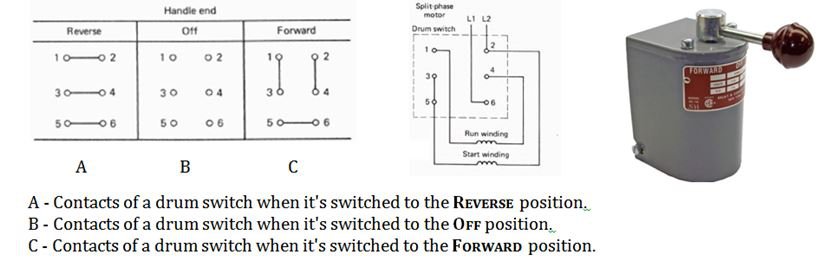

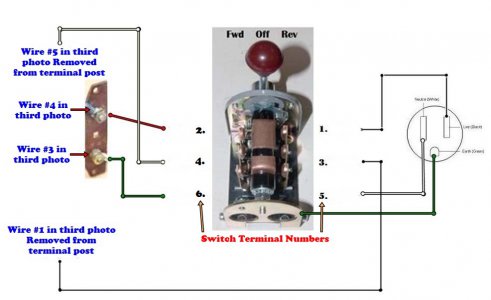

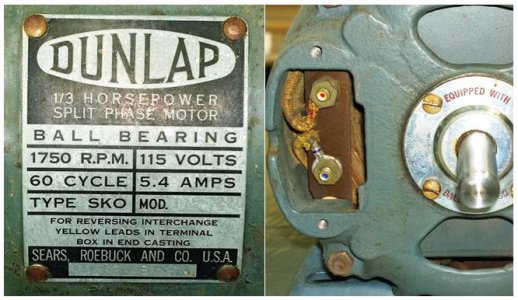

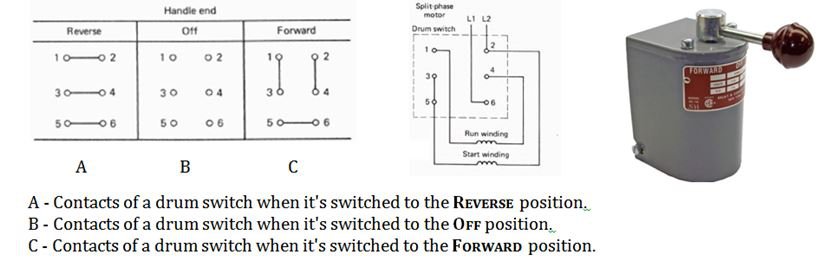

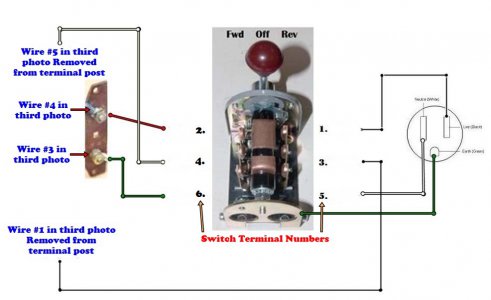

Over the last couple of weeks, I’ve read way too many posts about how to do this and it seems the more I read, the less I understand. The motor data plate and terminal box are shown in the first photo. The second photo shows the drum switch I’m using and the third photo shows the internal motor wiring. I’ve numbered them for ease of reference as most of them appear to be yellow except for the two green wires. The last photo shows how I wired in the drum switch and it spins in the right direction both ways but I’m unsure if it is running on the start windings. Also, I capped off and did not use wires 1 and 2 (3rd photo) which is where the cord was originally connected - Is that OK or is there a more correct way to wire in the reverse switch?

I truly appreciate any help you can offer as I’m quite ready to move onto the next phase in my lathe restoration.

NOTE: See Post #4 for correct diagram for the Furnas R-1 drum switch. The diagrams above are for the "other" type of switch.

I truly appreciate any help you can offer as I’m quite ready to move onto the next phase in my lathe restoration.

NOTE: See Post #4 for correct diagram for the Furnas R-1 drum switch. The diagrams above are for the "other" type of switch.

Last edited by a moderator: