- Joined

- Oct 29, 2012

- Messages

- 1,328

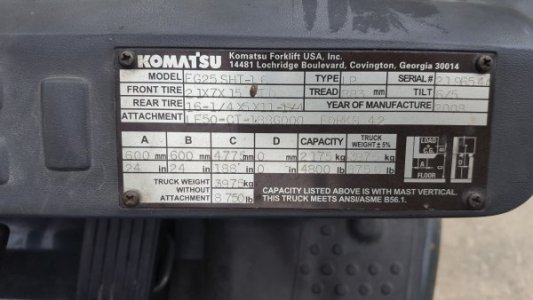

I got a great deal on a forklift through one of my customers. I don't know much about forklifts and I think I might have gotten something unsuitable for my needs. My plans for this thing were to bring heavy stuff to/from the yard and the shop. This forklift won't drive 3ft across dry dirt or grass before it gets "stuck."

The first and most obvious problem is the tiny and smooth warehouse tires. They suck so bad that I swear I saw them lose traction sitting on dry level pavement with the forklift turned off.

The other problem is the forklift has a differential which isn't of the "limited slip" variety, and no suspension. So any time it gets on a surface of unspecified flatness, one wheel comes of the ground, and that wheel is invariably a drive wheel, and the drive wheel just spins in the air. "Stuck"

Do I need to send this forklift back? Trade it in? Is the problem with the forklift or the operator (me)? Is there anything I can do to make this forklift work for me?

Note: the forklift is "stuck" in all attached pictures. It got "stuck" 5 times on the trip from the street to the shop on the temporary wooden driveway.

The first and most obvious problem is the tiny and smooth warehouse tires. They suck so bad that I swear I saw them lose traction sitting on dry level pavement with the forklift turned off.

The other problem is the forklift has a differential which isn't of the "limited slip" variety, and no suspension. So any time it gets on a surface of unspecified flatness, one wheel comes of the ground, and that wheel is invariably a drive wheel, and the drive wheel just spins in the air. "Stuck"

Do I need to send this forklift back? Trade it in? Is the problem with the forklift or the operator (me)? Is there anything I can do to make this forklift work for me?

Note: the forklift is "stuck" in all attached pictures. It got "stuck" 5 times on the trip from the street to the shop on the temporary wooden driveway.