- Joined

- Feb 8, 2014

- Messages

- 11,144

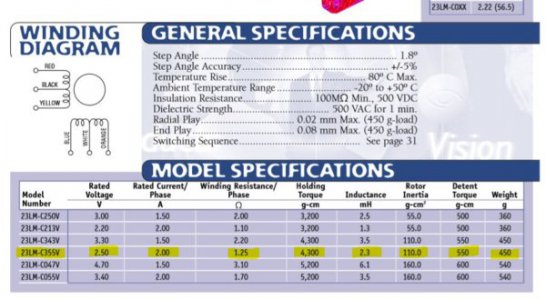

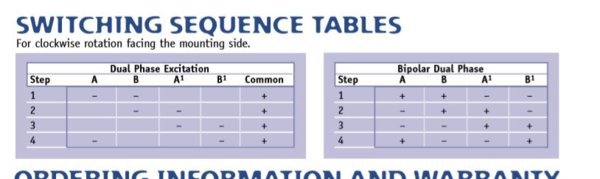

It still looks like the Vexta steppers might be the most useful, given that any data seems to be unavailable for the Elcom motors. Most steppers are 1.8° motors, the microstepping is done in the stepper drive, the motor just does what it's told. The problem is that you did not get any stepper drives in your box of goodies, but the good news is that they can be bought inexpensively on Ebay.

Given their size and current, I'm going to guess around 280 oz/in. These should be able to run a large table top machine at reasonable resolutions and speeds. Now are you going to push a 1/2'' bit through aluminum with them?..... No, but for the work that you describe above they would work fine.

Given their size and current, I'm going to guess around 280 oz/in. These should be able to run a large table top machine at reasonable resolutions and speeds. Now are you going to push a 1/2'' bit through aluminum with them?..... No, but for the work that you describe above they would work fine.