Hi all,

I’ve tried this on another forum already with no luck but here goes: so i recently bought a colchester mascot 1600 for a reasonable price given the state of it, problem is that it came with no tool holders i have no idea what kind of post it is thats sitting on there now here’s a picture:

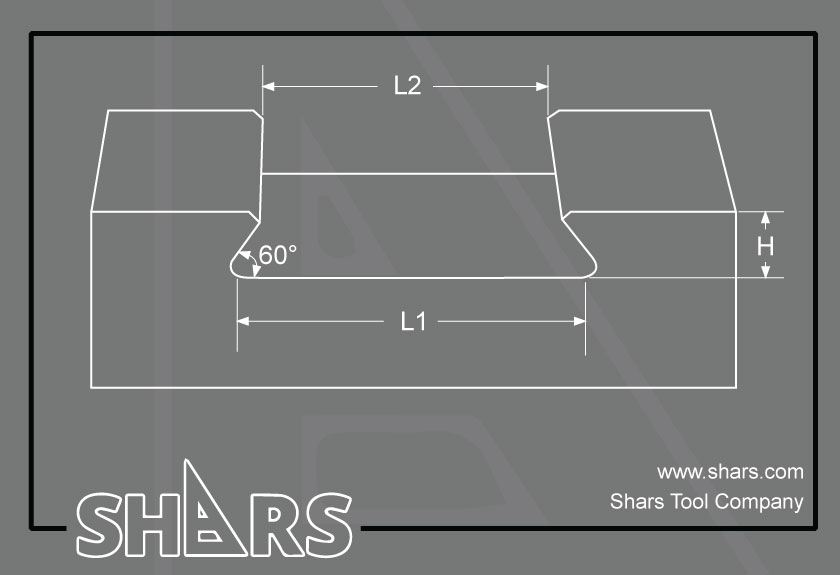

I have only ever worked with the dickson type toolposts so this is very unfamiliar to me. Some measurments: the total width of the block is 106 by 106 mm, the height is 80 mm and the Outer end of the dovetail is 73mm ( metric lathe, so sorry for no values in inches)

I have searched the web far and wide for something that resembles it, but to no avail. Hoping to have Some luck here since i just wanna buy Some holders for this or else i gotta buy a new post.

I’ve tried this on another forum already with no luck but here goes: so i recently bought a colchester mascot 1600 for a reasonable price given the state of it, problem is that it came with no tool holders i have no idea what kind of post it is thats sitting on there now here’s a picture:

I have only ever worked with the dickson type toolposts so this is very unfamiliar to me. Some measurments: the total width of the block is 106 by 106 mm, the height is 80 mm and the Outer end of the dovetail is 73mm ( metric lathe, so sorry for no values in inches)

I have searched the web far and wide for something that resembles it, but to no avail. Hoping to have Some luck here since i just wanna buy Some holders for this or else i gotta buy a new post.