- Joined

- Mar 20, 2014

- Messages

- 440

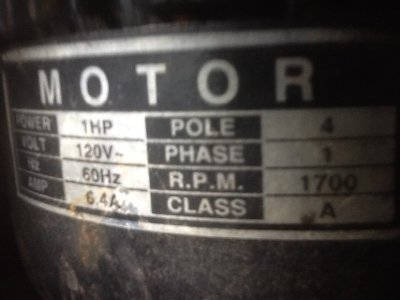

My H.F. 4X6 bandsaw has the original 1 HP motor that it came with. Don't know how much use it's had as I got it used. Today, while cutting a steel plate 5" wide by 1" thick (this took longer than any piece since buying it), when it got almost to cutting through the bottom, the blade stopped. I assume, as it was cutting through a tooth caught and jammed the blade. I lifted up on the saw and the blade began moving again. I figured that the belt was slipping, because surely, the motor has enough power to slip the belt, especially since I run the belt pretty loose to make speed changes easy. But, to my surprise, it was not the belt, the motor was stopping, and as soon as I lifted the blade up it started turning again. I tried this a few more times and each time the motor stalled rather than slip the fairly loose belt. Are these H.F. motors that underpowered? The motor temp was about 138* F. with a laser thermometer, if that makes a difference. Is this motor junk? I would think with a little more power the blade should have pulled right through the cut. Does this motor have replaceable brushes, and would worn brushes cause the lack of power? I can probably fix it If you electrical gurus tell me what to fix. If need be, I can get a new motor, cause the saw is in really good shape, but I'd rather fix this one if I can. Please Help! Thanks, JR49

EDIT, Forgot to say, blade is 10-14 TPI, so there were plenty of teeth in the cut

EDIT, Forgot to say, blade is 10-14 TPI, so there were plenty of teeth in the cut