- Joined

- Jan 27, 2020

- Messages

- 8

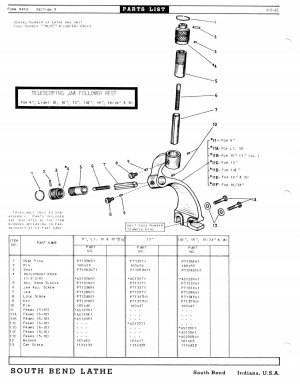

A non-working telescoping follower rest came along with my 9" workshop lathe. I have never used a follower rest, and it looks like this will come in very handy if I can get it together again. When I received it, the knurled end caps were rusted to the steel sleeves that house the brass bearing rod jaws. The previous owner had beat on everything trying to get it all apart. I finally got it 90% apart with the exception of one knurled cap is still rust welded to the iron sleeve. as soon as the Kroil does it's job , and I can separate those two pieces, I will begin the re-assembly.

I had to make the 5/8" brass bearing rod jaws, and have yet to drill and tap the hole in the top/rear of them. My problem is that not all of the parts came with this follower rest. There are telescoping rods that attach the knurled end caps to the brass rod jaws, but I don't have any ideaif they are right or left handed threads, or if they are fine or coarse pitch.

Also there are some spring clips and small pins that I assume are there to ensure that the end caps don't vibrate loose which are missing as well. These can be fabricated.

Can anyone with knowledge about these follower rests help me out by telling me the length, diameter and thread pitch of the telescoping jaw adjusting screws on a 9" South Bend Telescoping Follower rest?

Thanks

I had to make the 5/8" brass bearing rod jaws, and have yet to drill and tap the hole in the top/rear of them. My problem is that not all of the parts came with this follower rest. There are telescoping rods that attach the knurled end caps to the brass rod jaws, but I don't have any ideaif they are right or left handed threads, or if they are fine or coarse pitch.

Also there are some spring clips and small pins that I assume are there to ensure that the end caps don't vibrate loose which are missing as well. These can be fabricated.

Can anyone with knowledge about these follower rests help me out by telling me the length, diameter and thread pitch of the telescoping jaw adjusting screws on a 9" South Bend Telescoping Follower rest?

Thanks

Attachments

Last edited: